S-5 Clamps & Mounting

Shop the industry’s leading metal roof mounting solutions. S-5! products, including clamps, snow bars, and solar mounting systems, are designed for reliability and performance on metal roofs of all types.

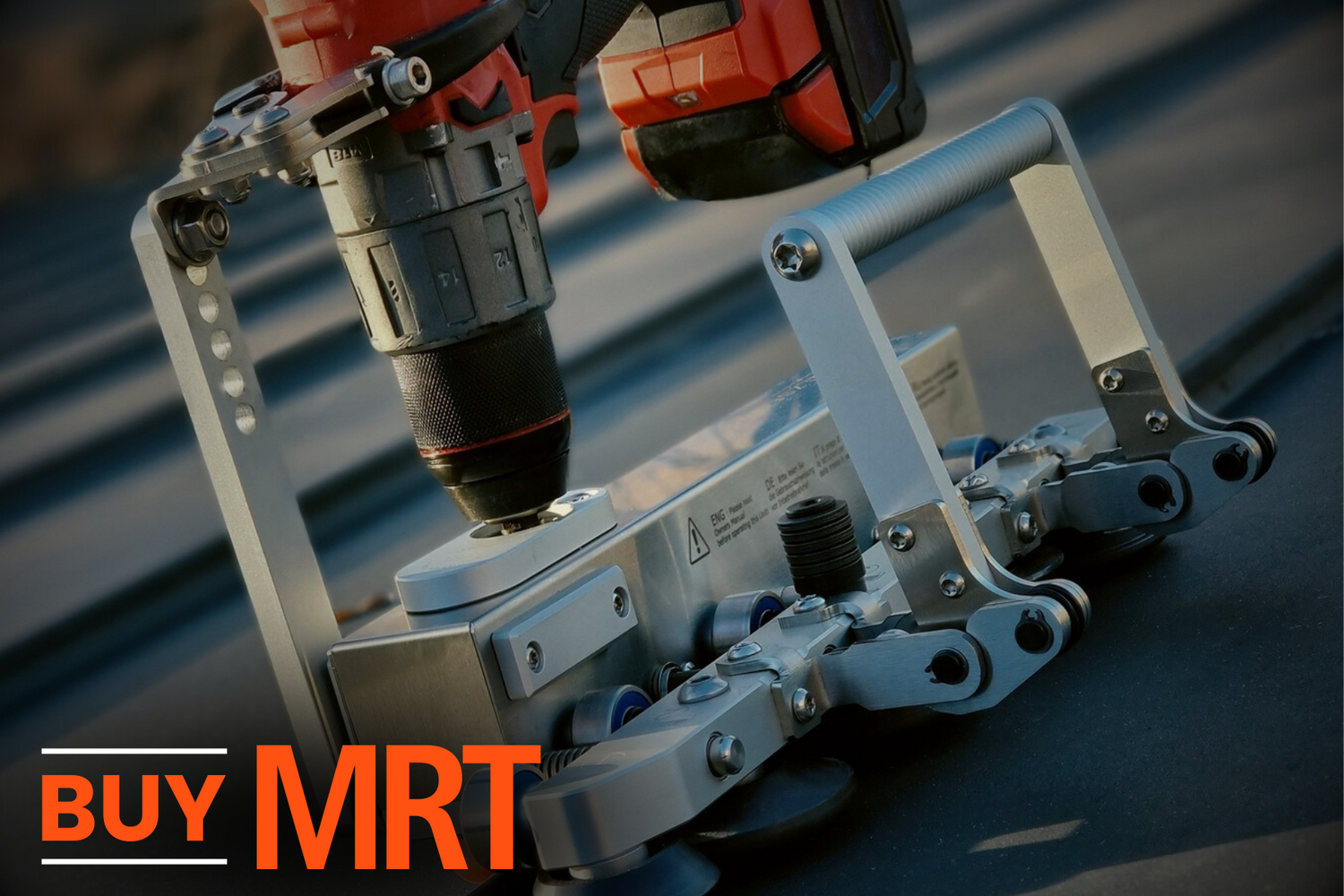

Metal Roofing Tools

Find the tools you need for precision and durability in metal roofing projects. From seamers and benders to pliers and gutter tools, we offer high-quality products from trusted brands to help you work efficiently and effectively.

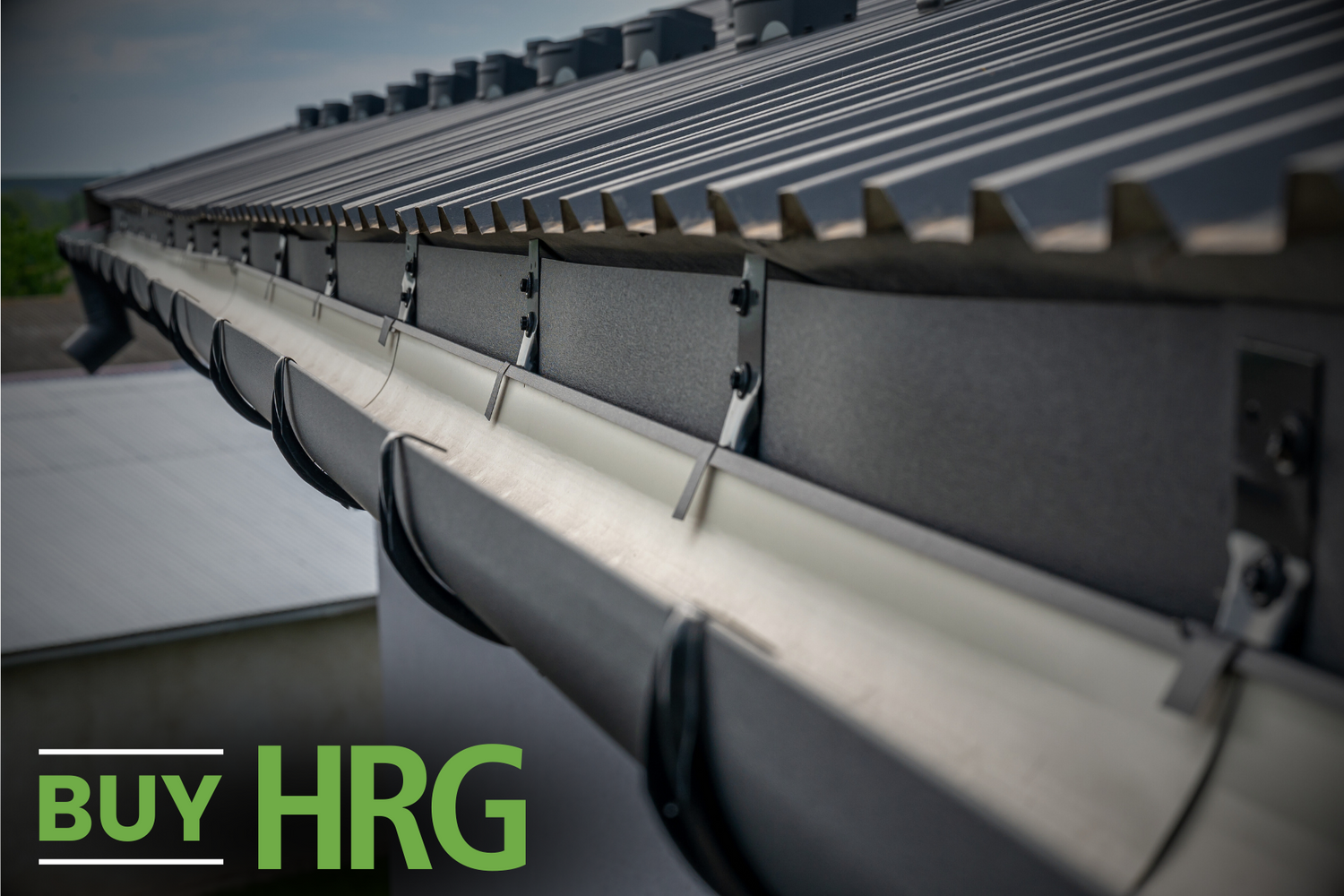

Half Round Gutters

Discover premium half-round gutters and accessories in copper, zinc, lead-coated, and painted finishes. We provide everything you need to create elegant, durable gutter systems for residential or commercial projects.

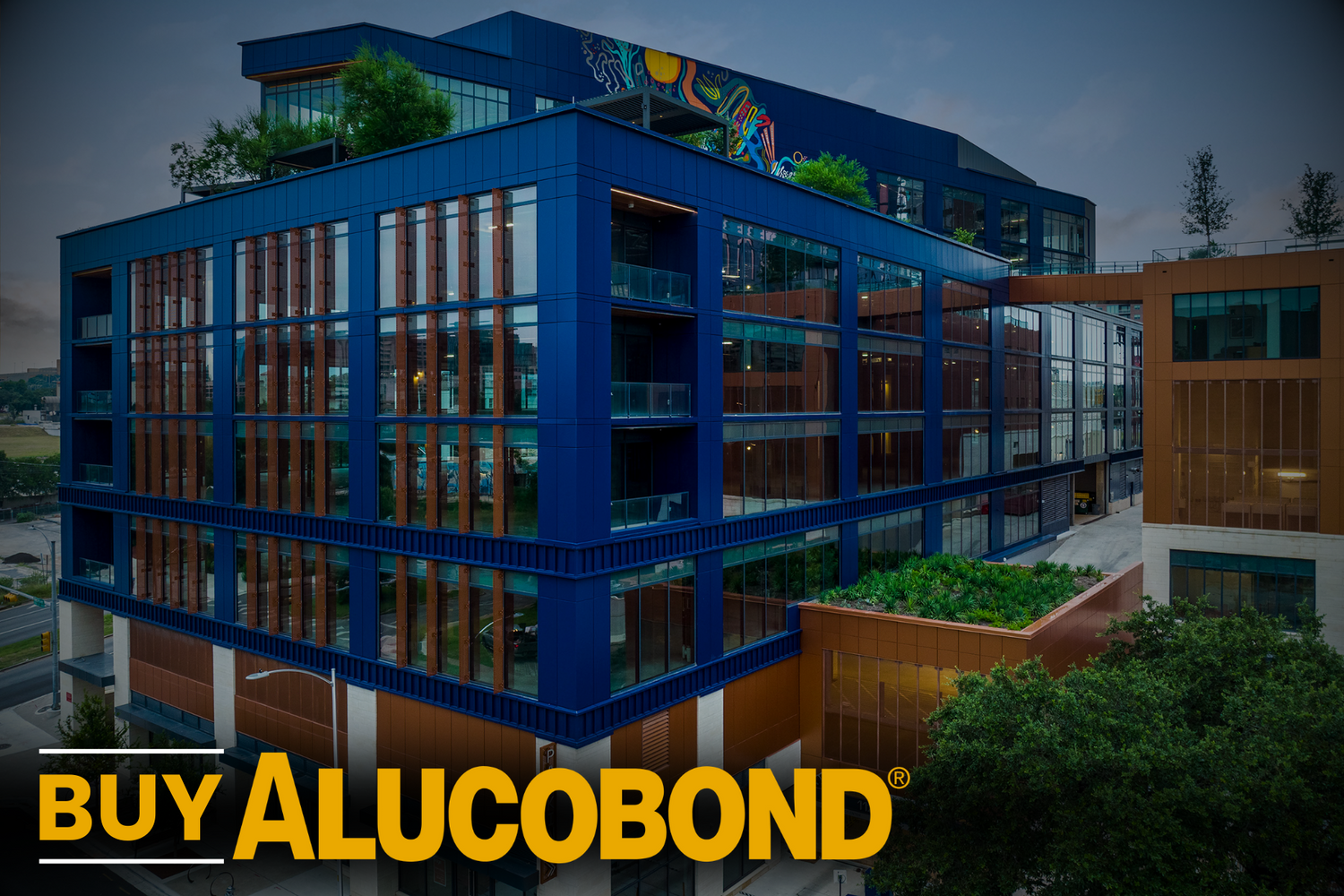

Cladding & Exterior Facade

Elevate your designs with top-tier cladding and exterior facade systems. Explore brands like Reynobond, Equitone, Trespa, and Alucobond, along with fasteners and accessories to create stunning, durable exteriors.

ALUCOBOND® Panels

Transform your projects with ALUCOBOND®, the industry leader in aluminum composite panels. Known for their exceptional durability, design versatility, and 50-year legacy, ALUCOBOND® panels are ideal for creating striking, long-lasting exteriors. Explore a wide range of colors, finishes, and thicknesses to bring your architectural vision to life.