SKU: 32001000 | Alucobond

Alucobond .040" Axcent Aluminum Sheets

Alucobond .040" Axcent Aluminum Sheets

Couldn't load pickup availability

Shipping Details

At Rapid Materials, we prioritize quick and efficient order processing to meet your needs.

Our team is available Monday–Friday, 8 AM to 5 PM EST, ensuring your orders are handled promptly. We’re dedicated to delivering your materials as quickly as possible. Have questions? Don’t hesitate to reach out—we’re always happy to assist!

Standard Shipping

- Orders placed by 1 PM EST are processed within 24 business hours and typically ship the same day.

- Orders received after 1 PM will ship the next business day.

Expedited Shipping

- For expedited orders, we’ll do our best to ship them the same day—even if placed after 1 PM EST.

Holiday Shipping

- We do not process or ship orders on major holidays.

- Some locations close during the last two weeks of the year for inventory processing. Specific details will be noted on product pages.

Please note: Some products may require additional handling time and will take longer than 24 hours to ship. For specific shipping details or lead times, refer to the individual product page or contact us directly—we’re here to help.

-

Description

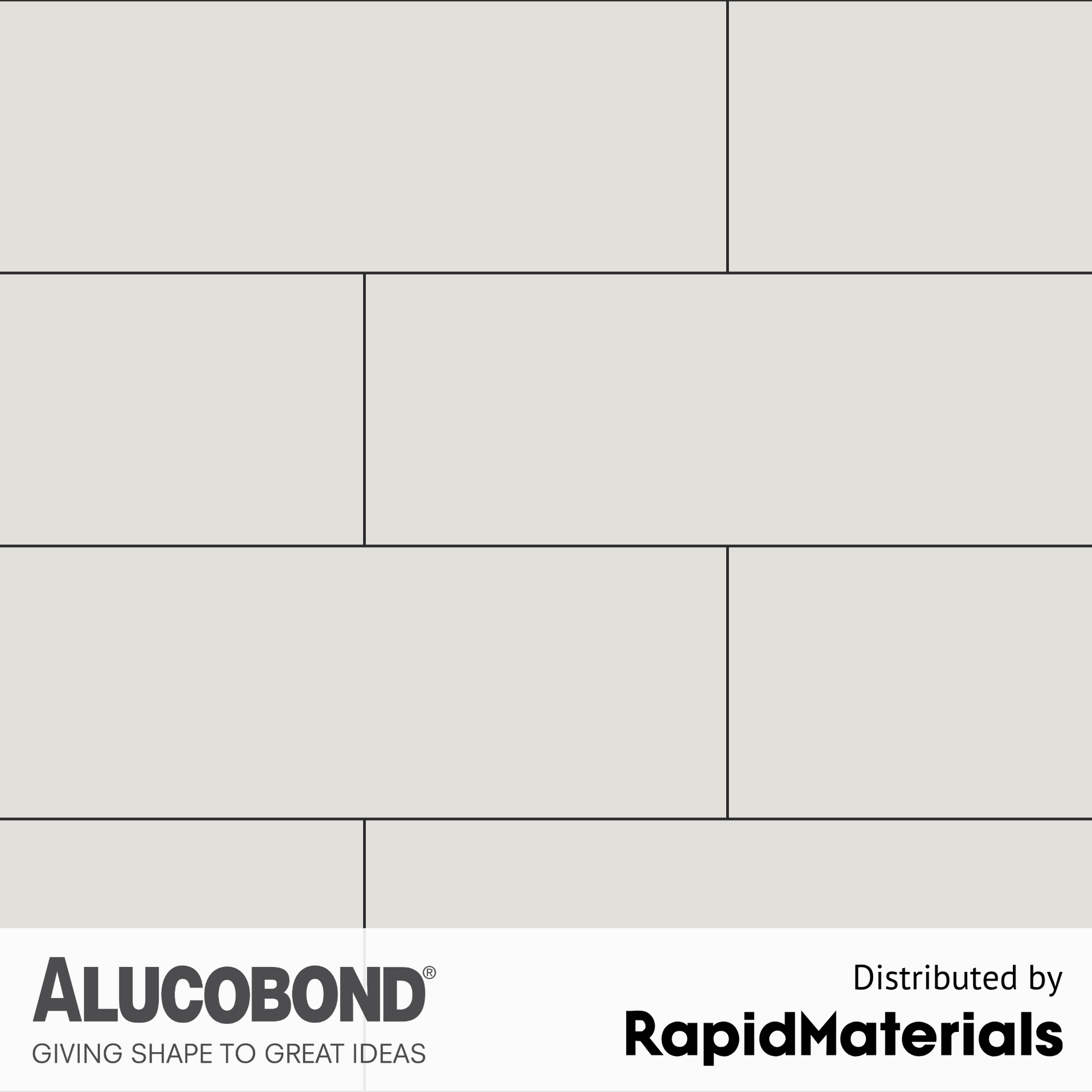

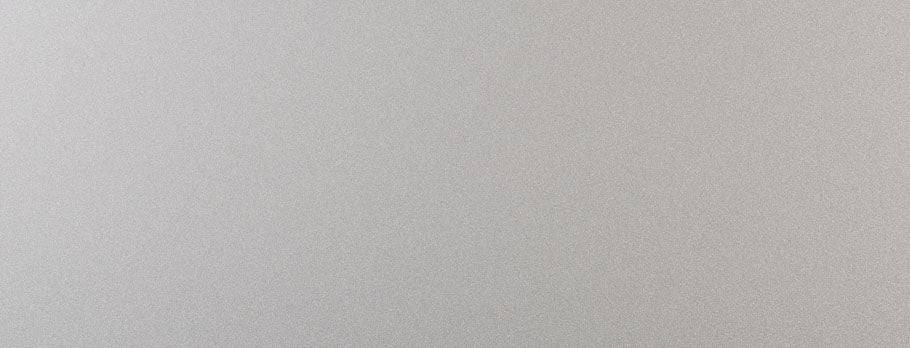

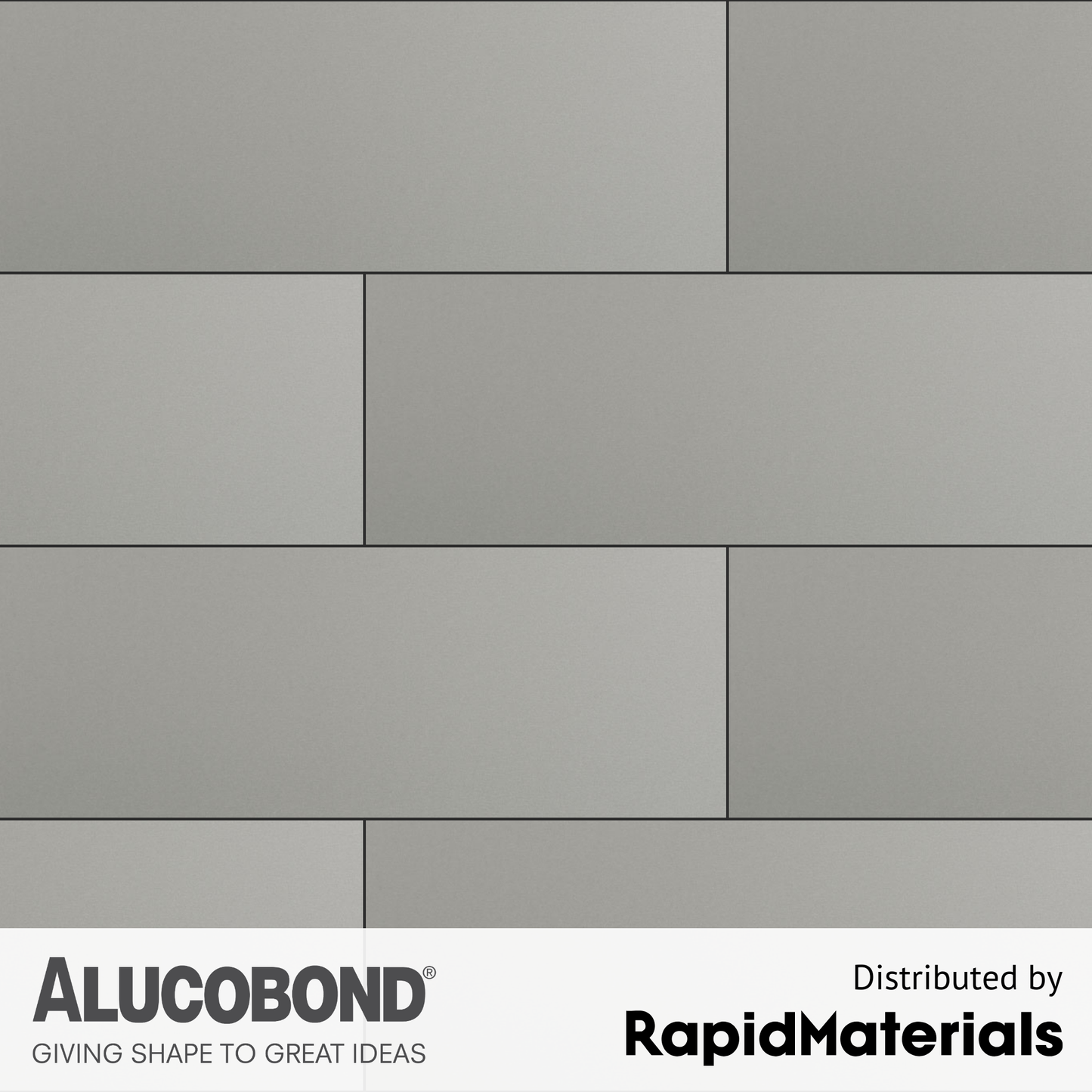

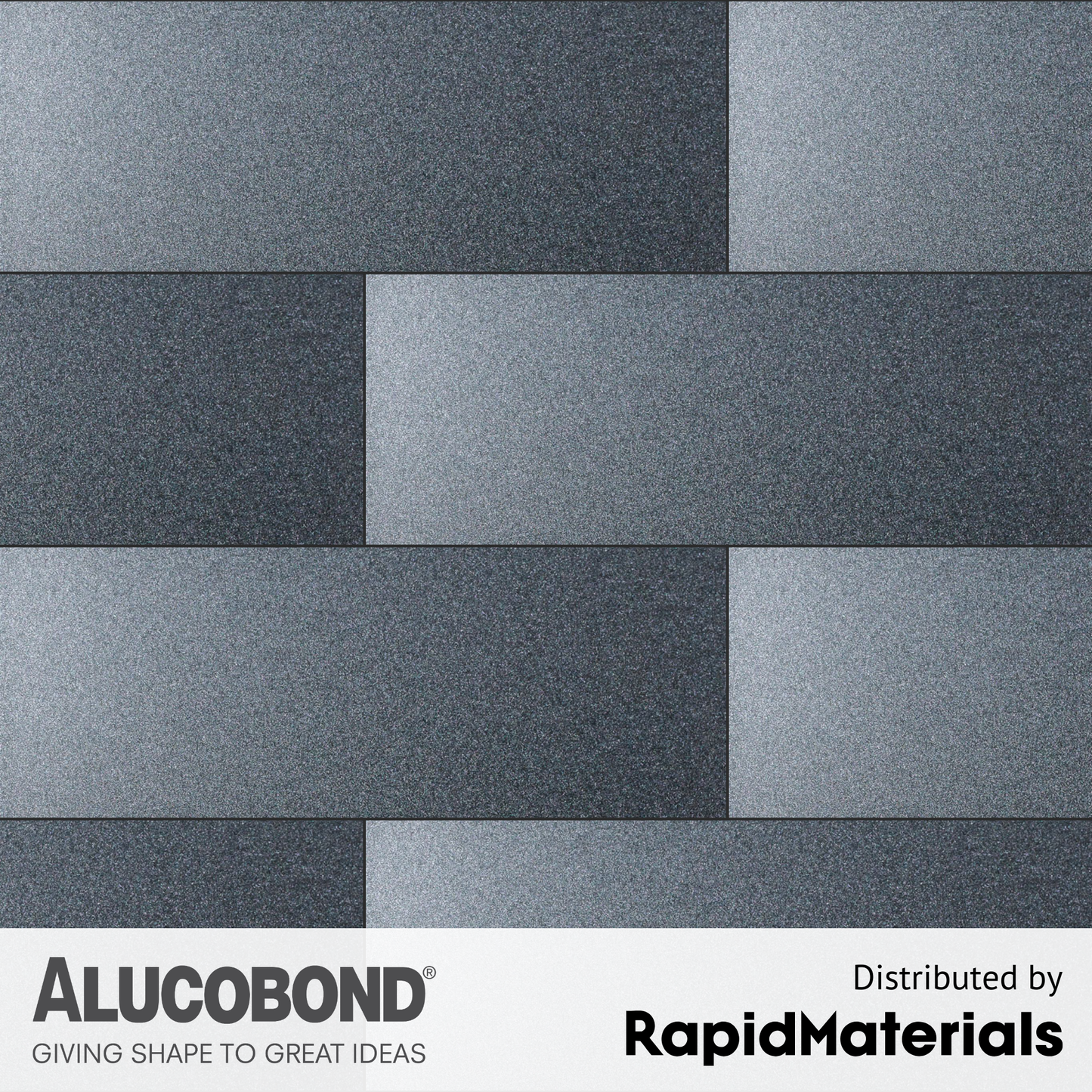

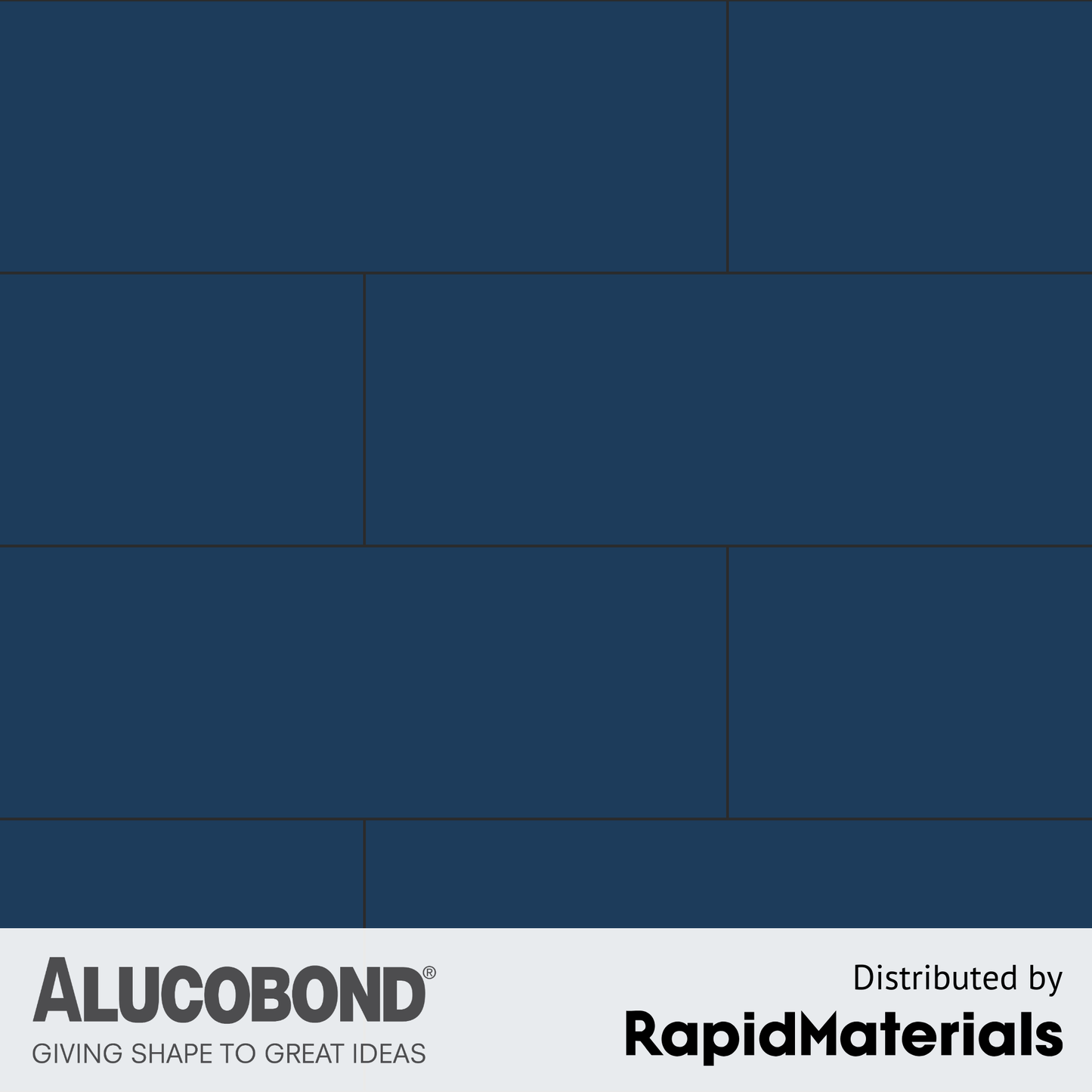

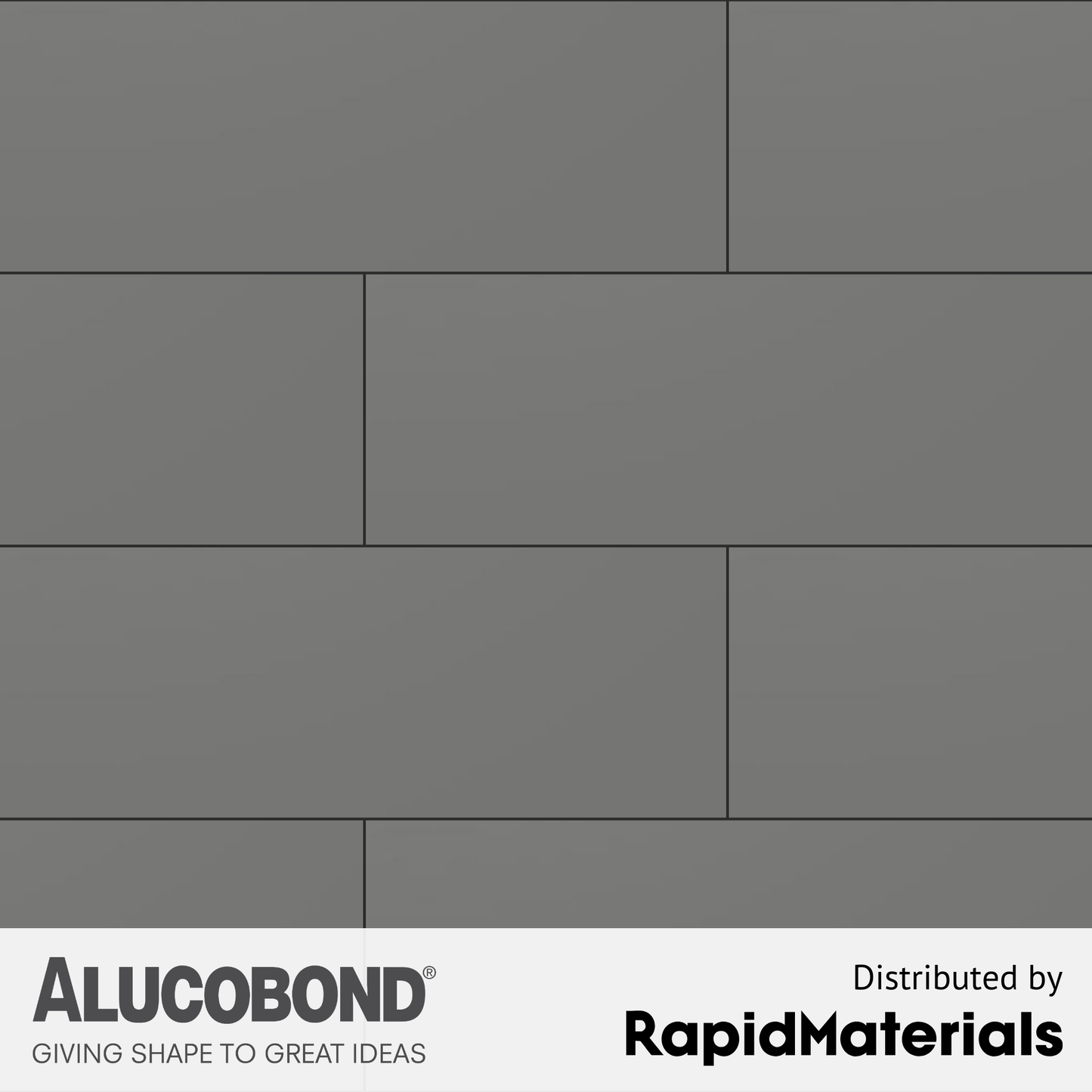

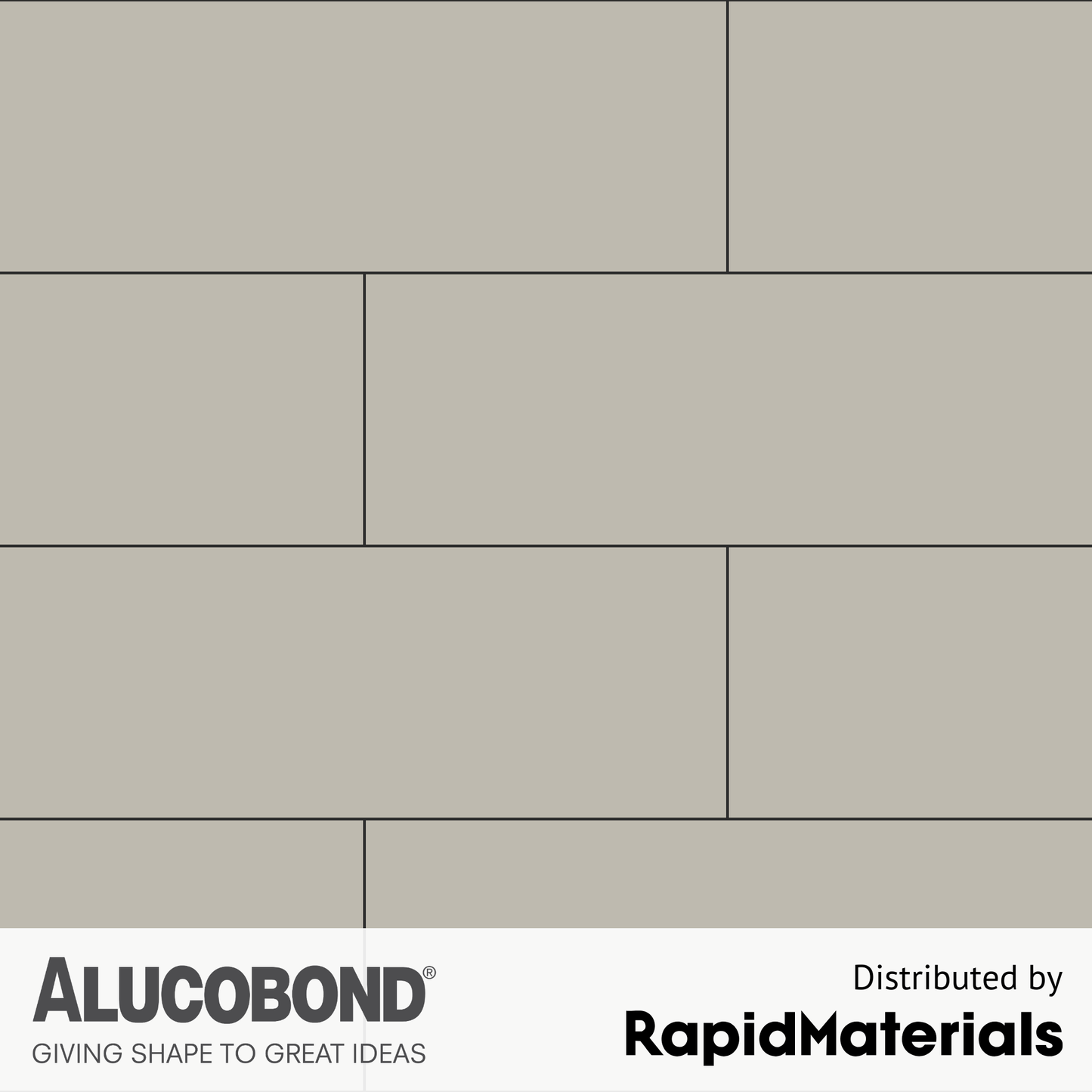

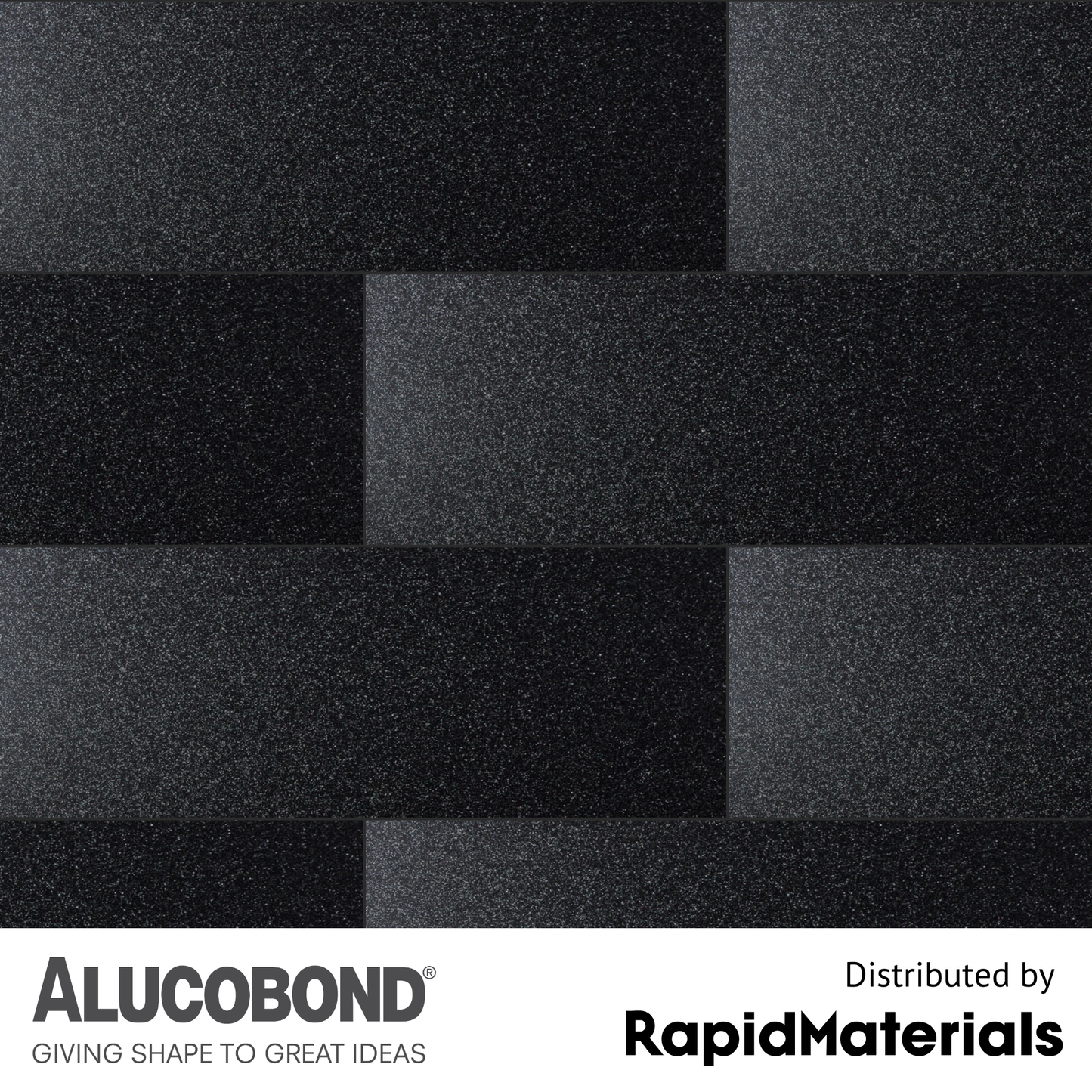

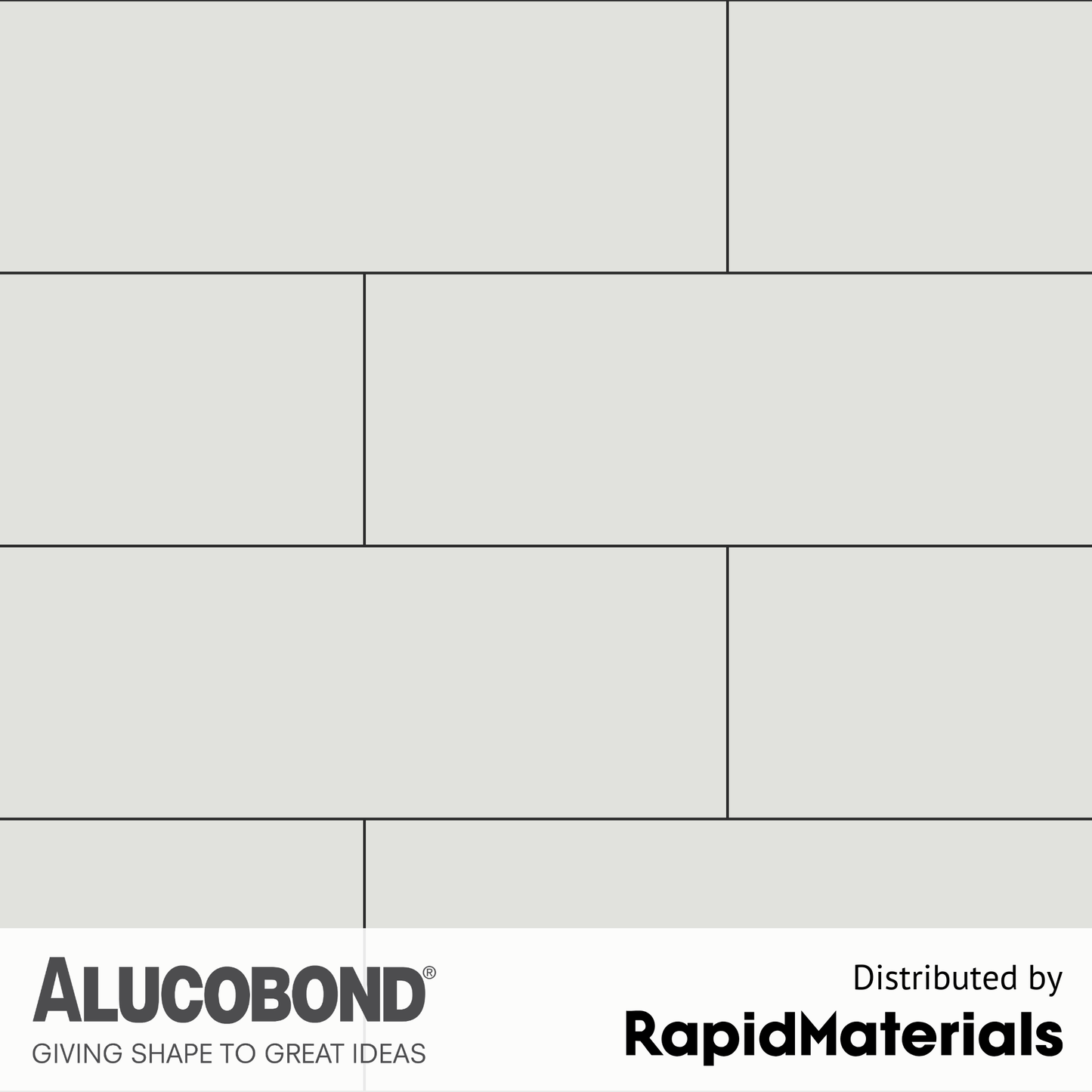

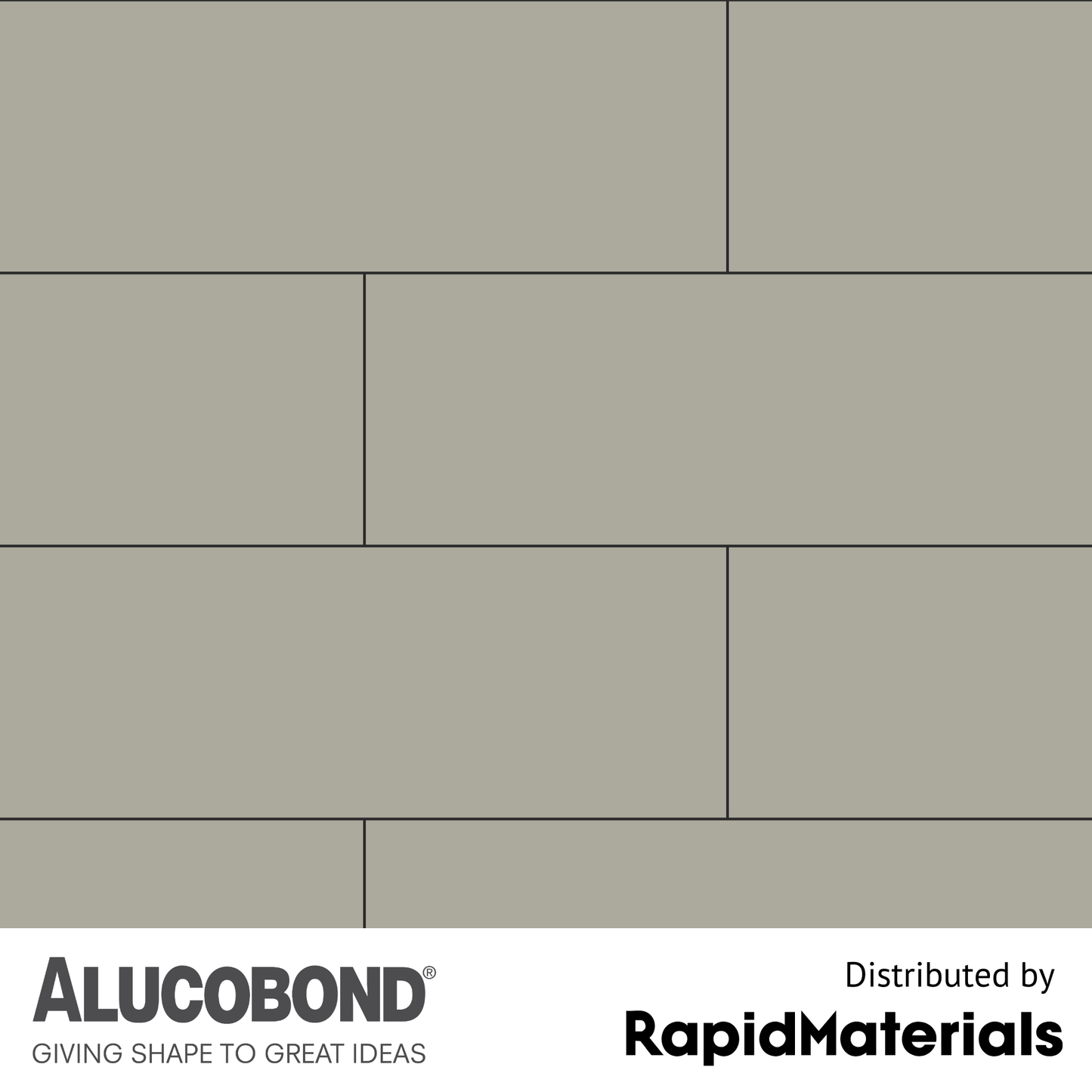

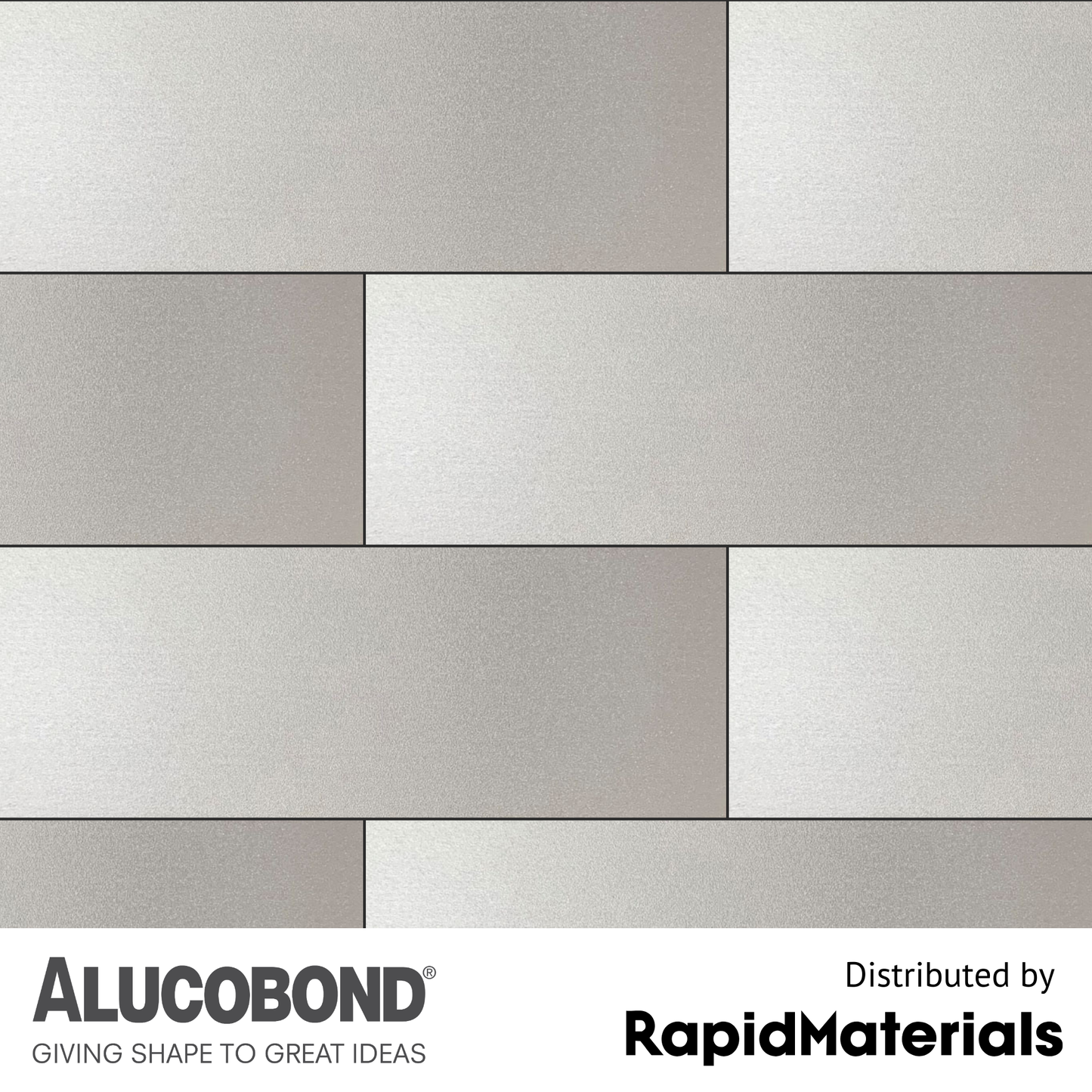

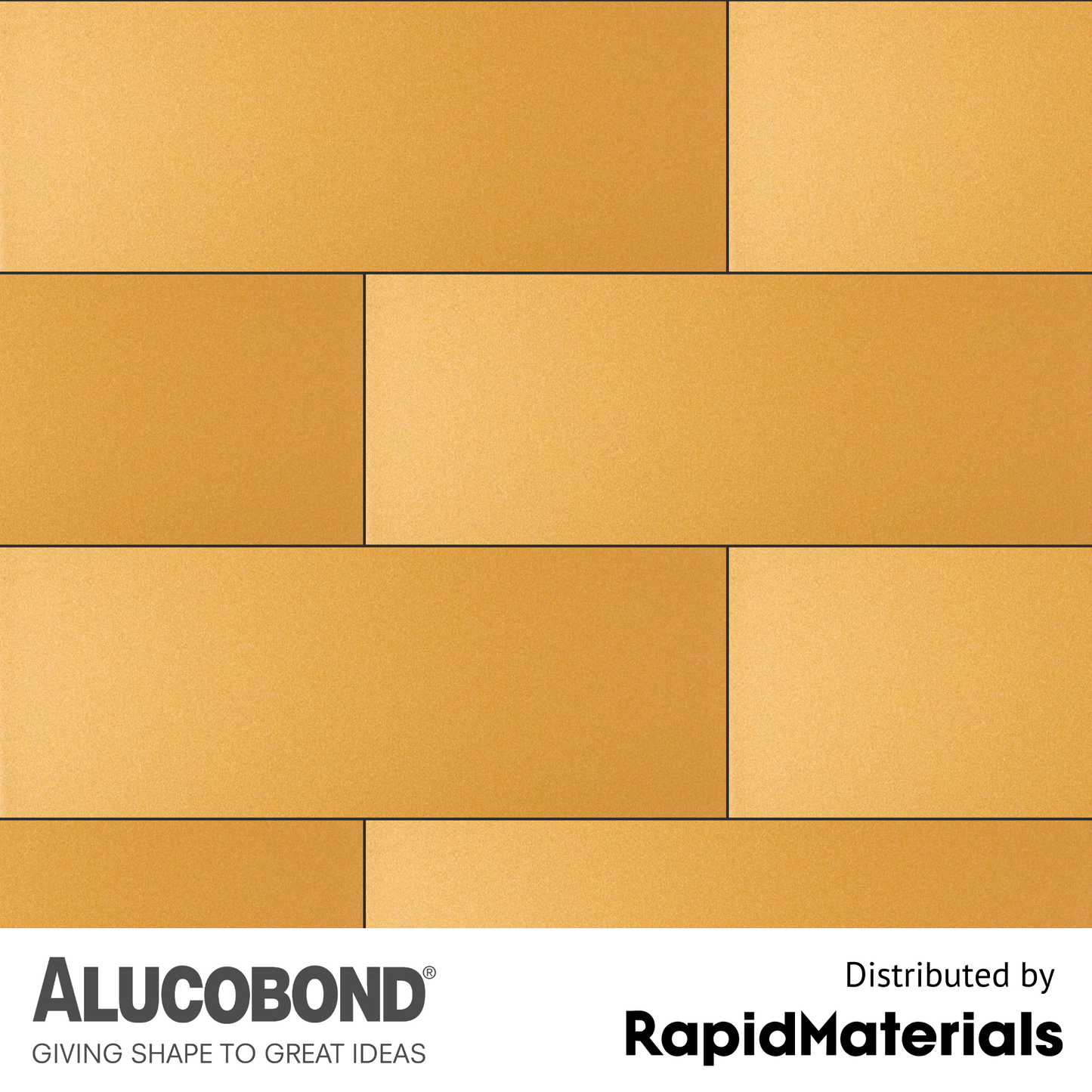

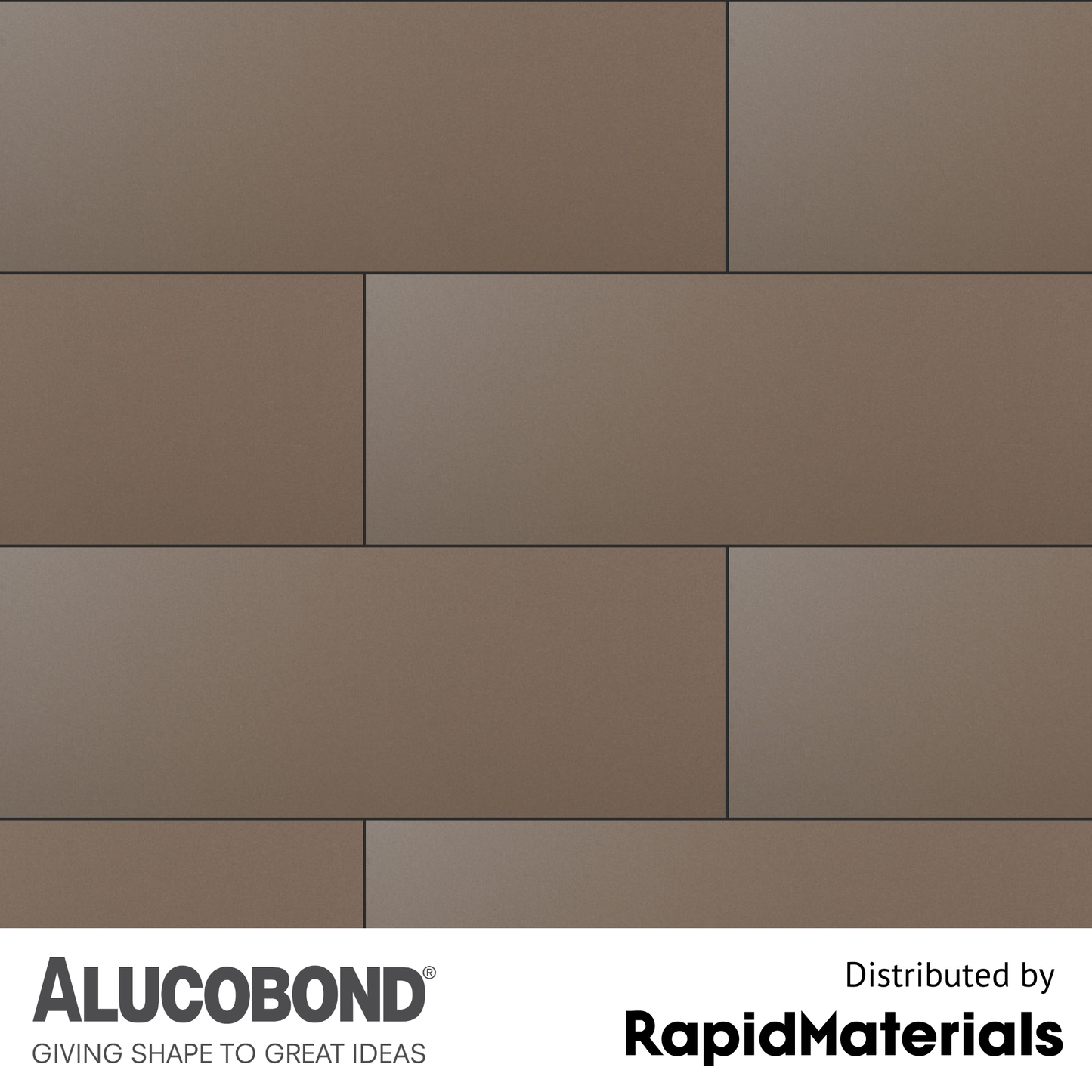

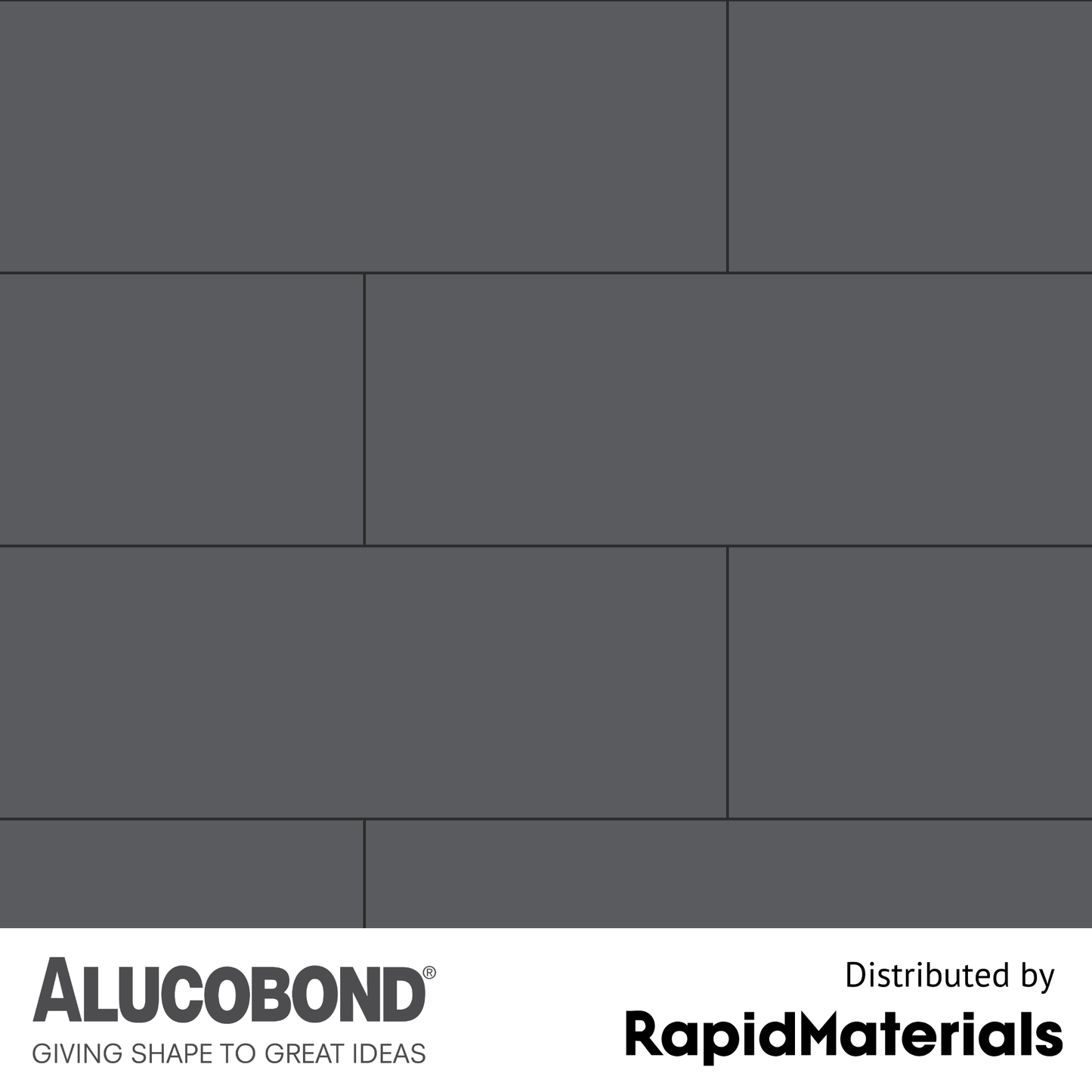

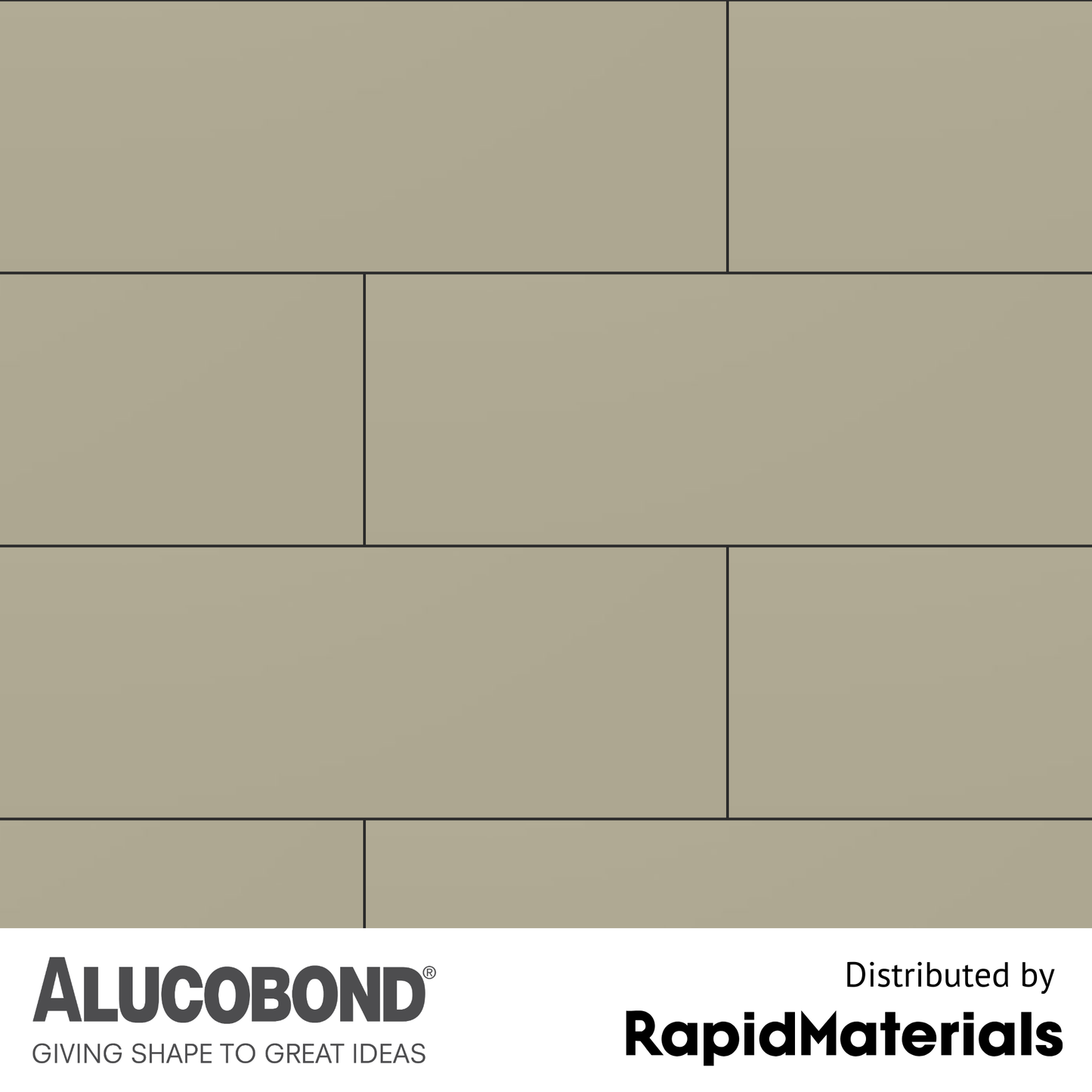

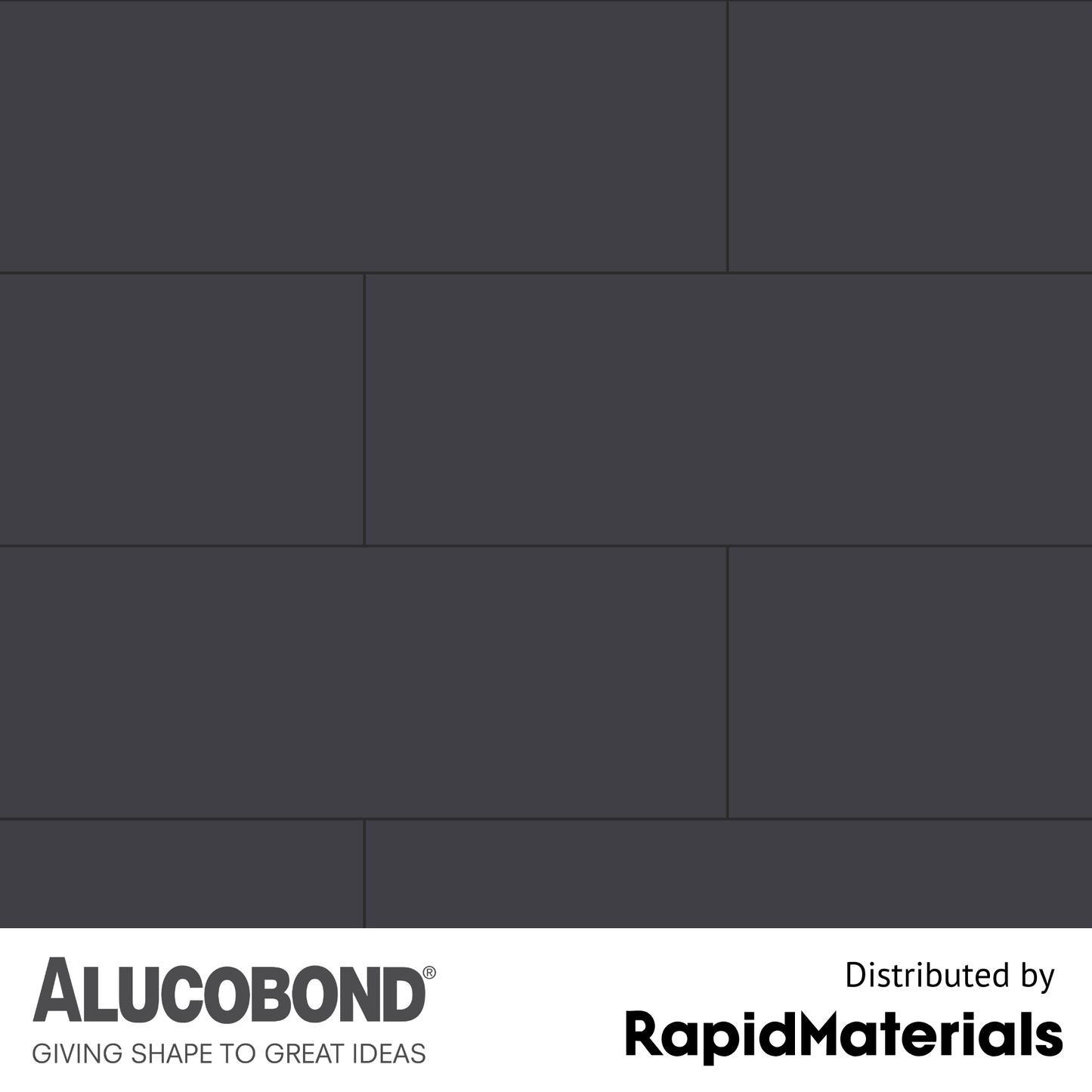

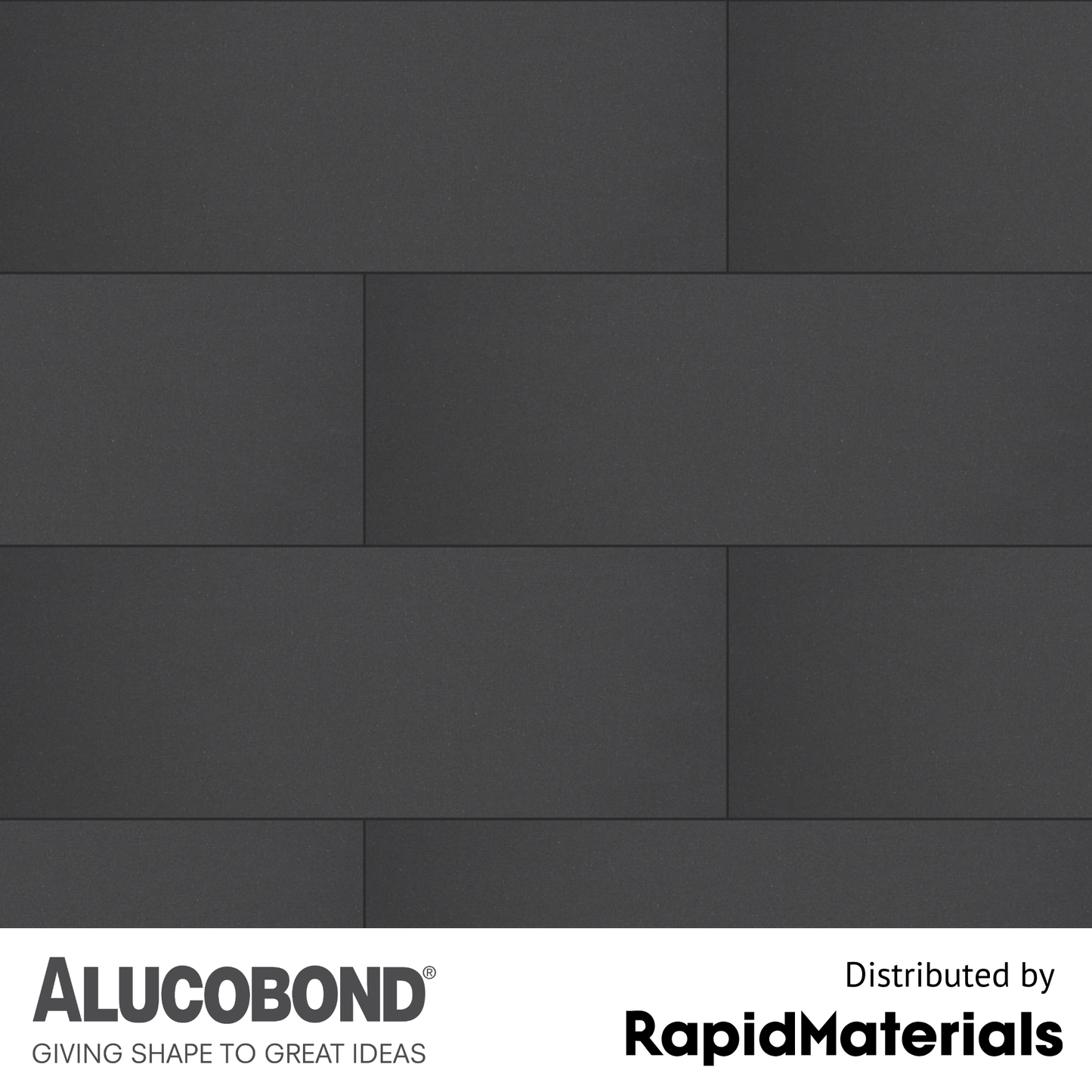

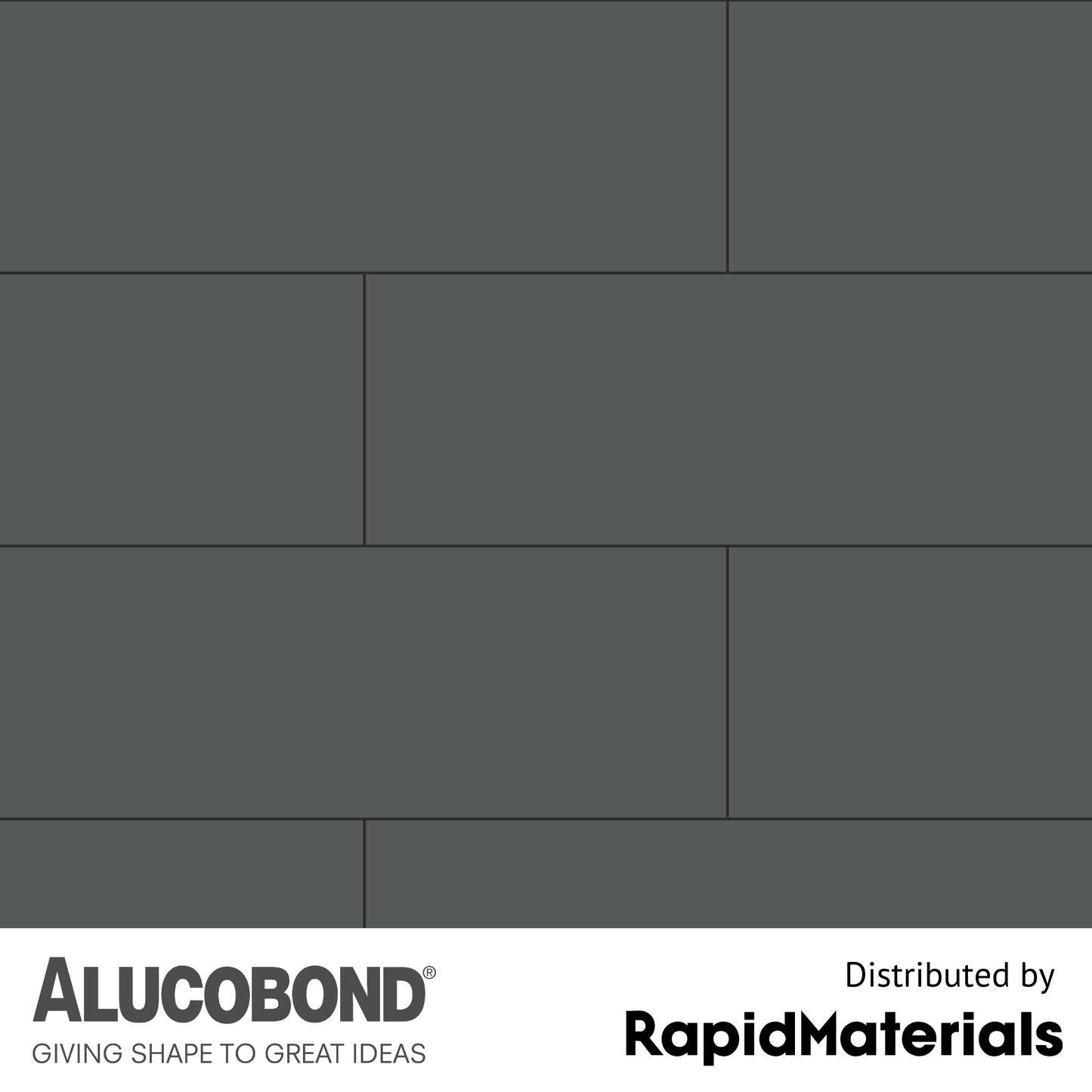

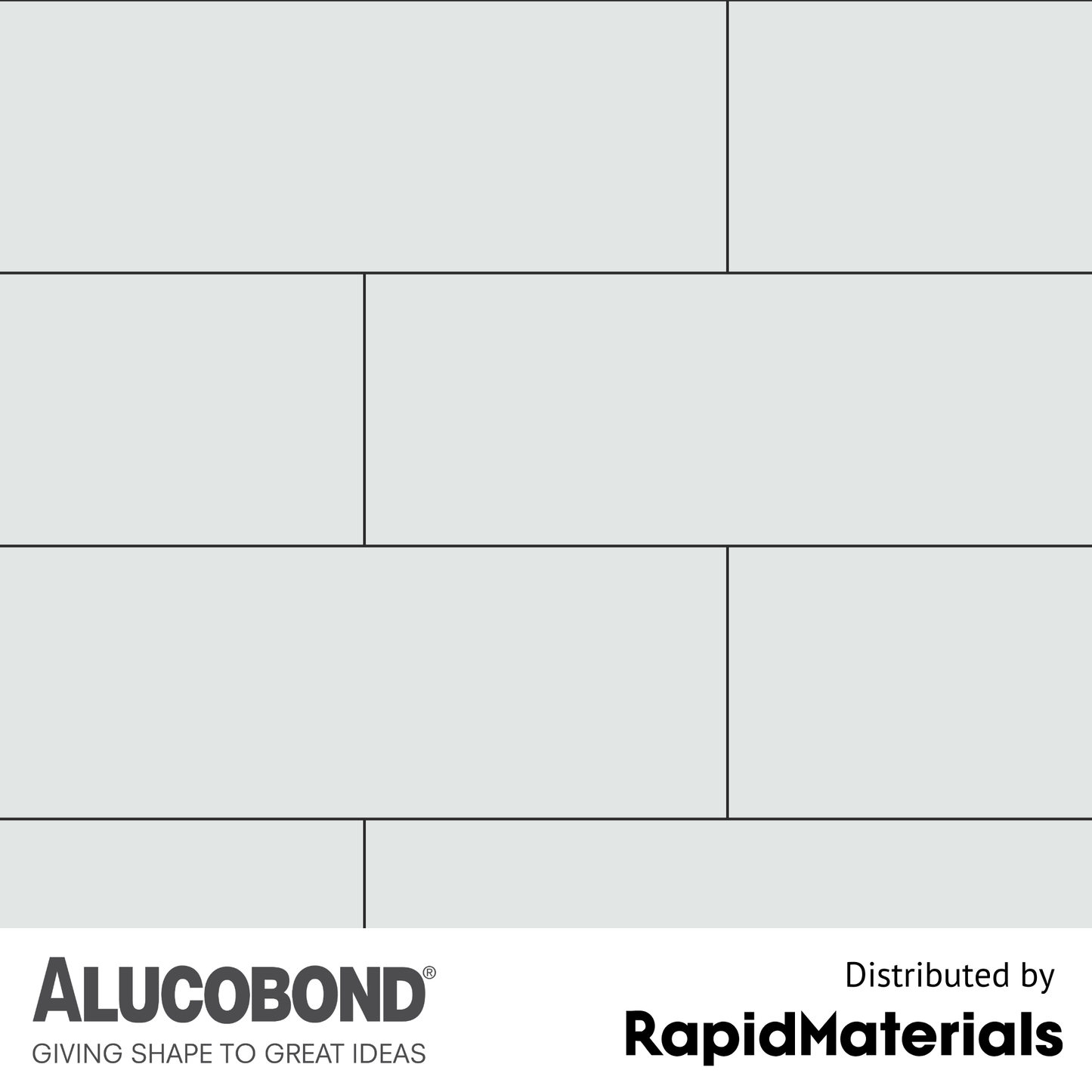

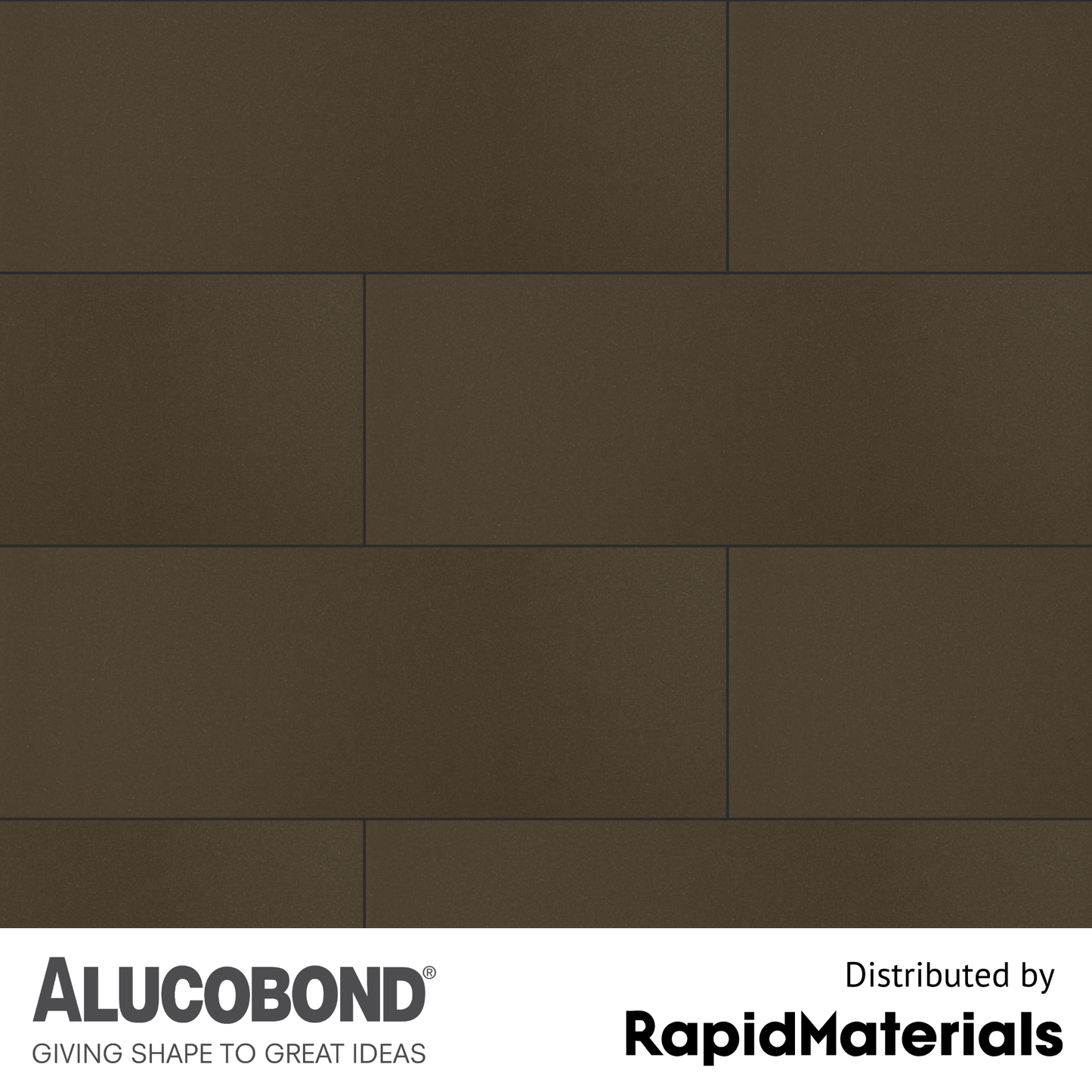

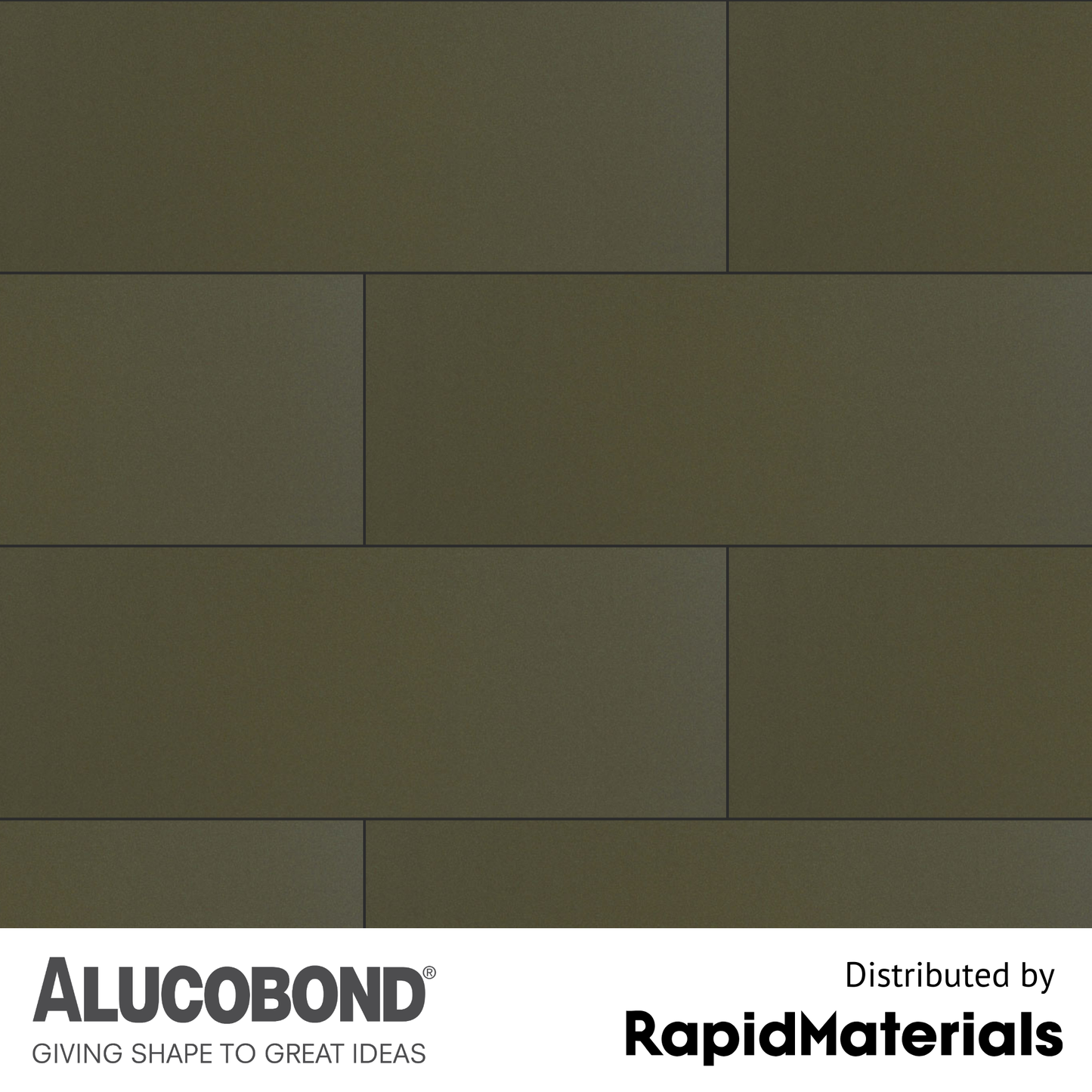

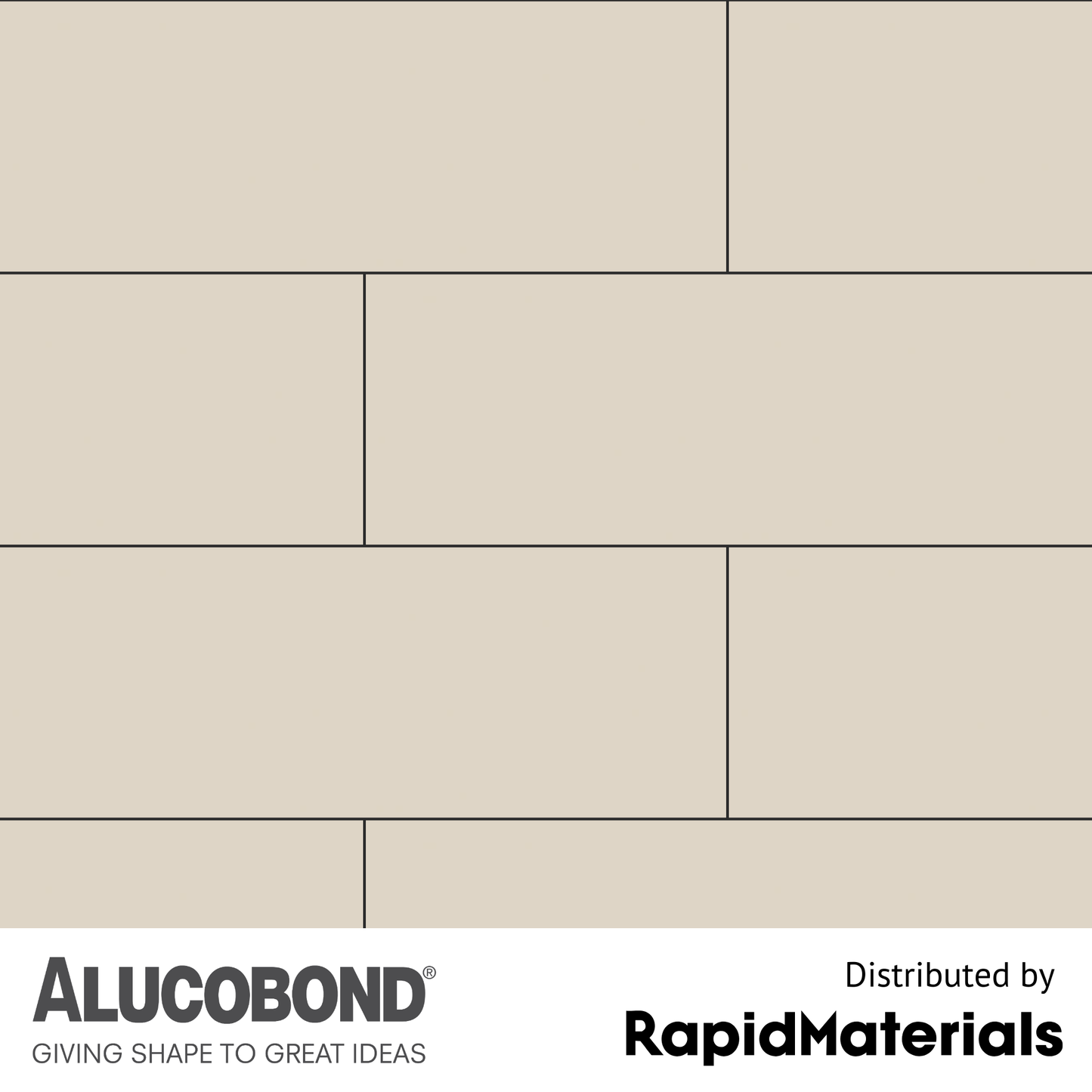

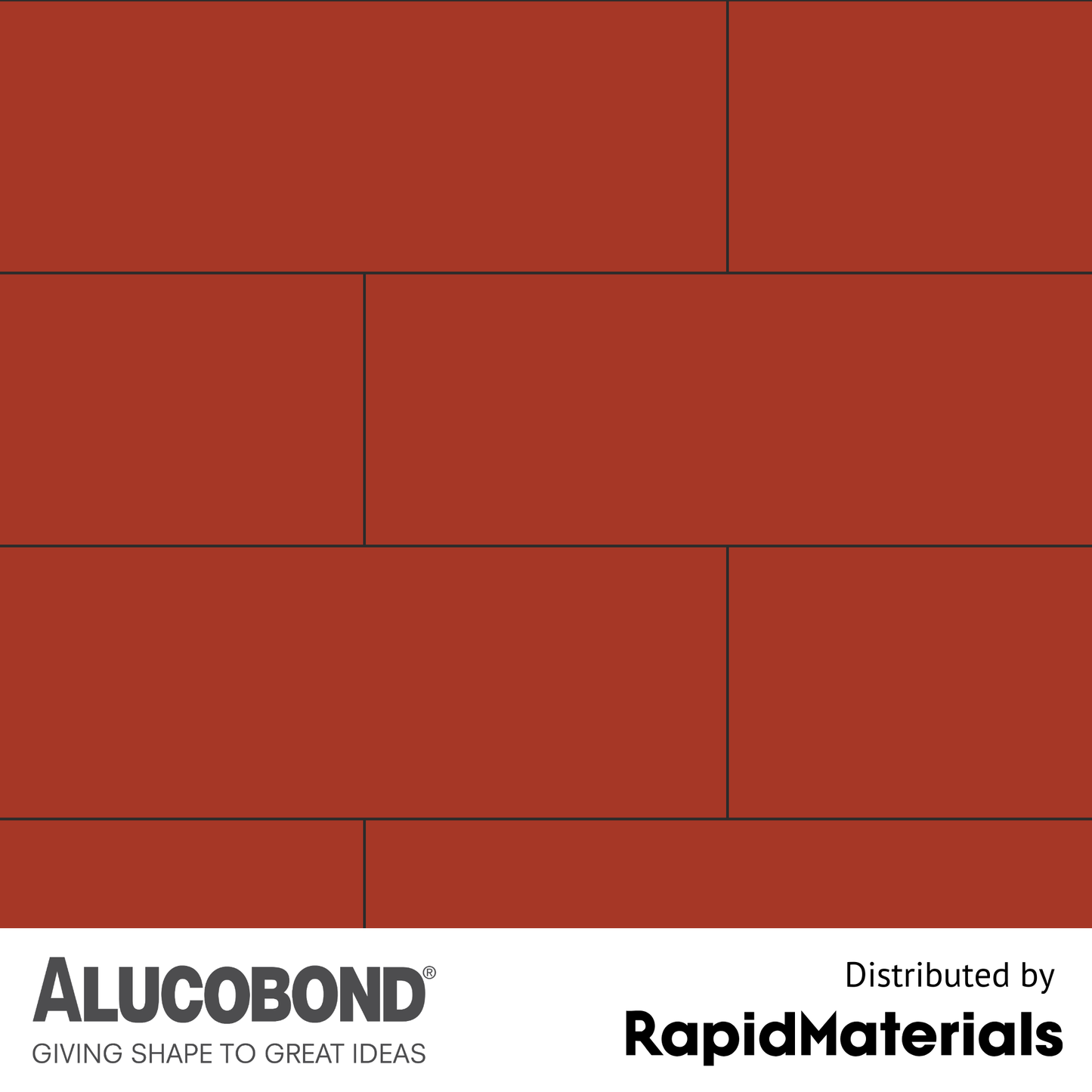

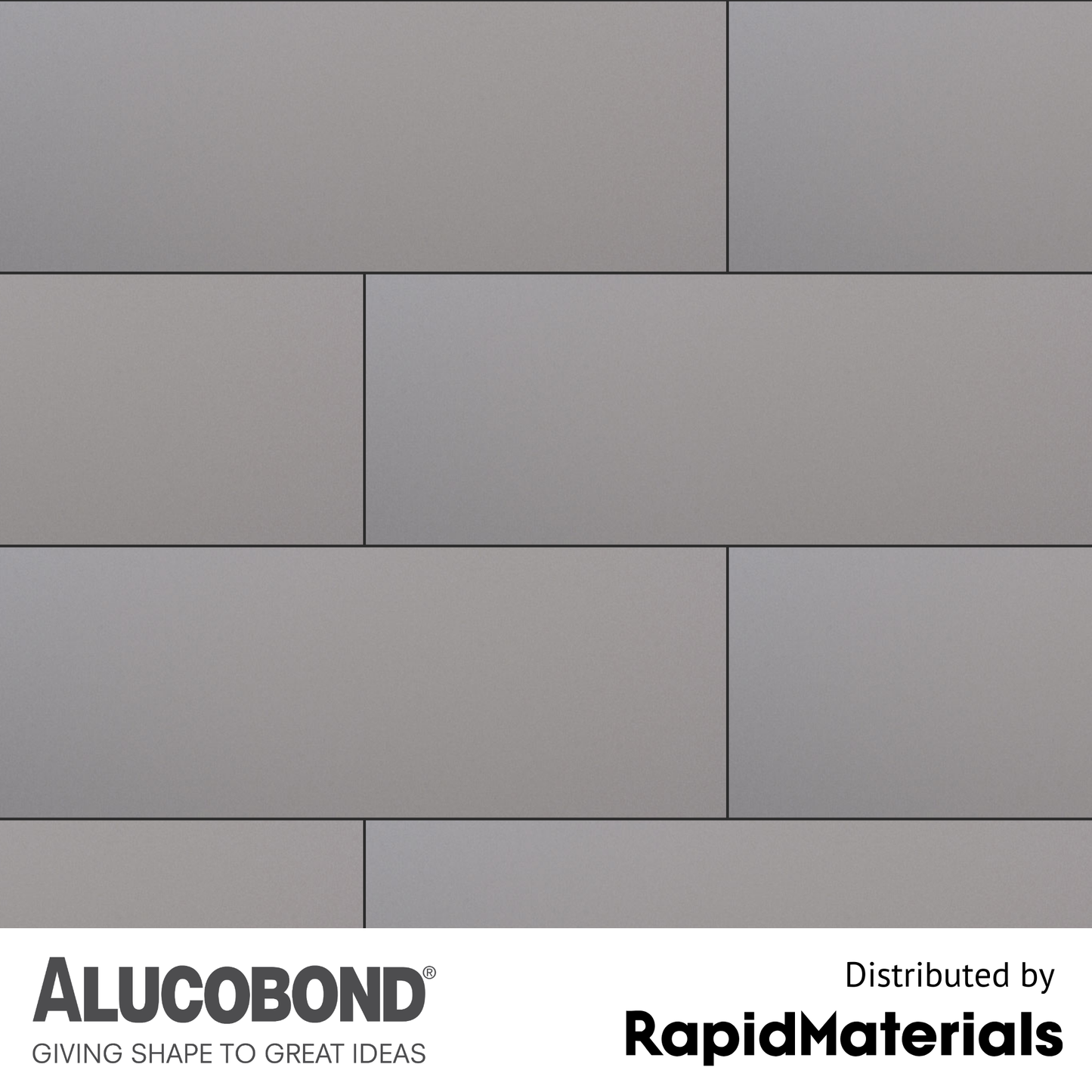

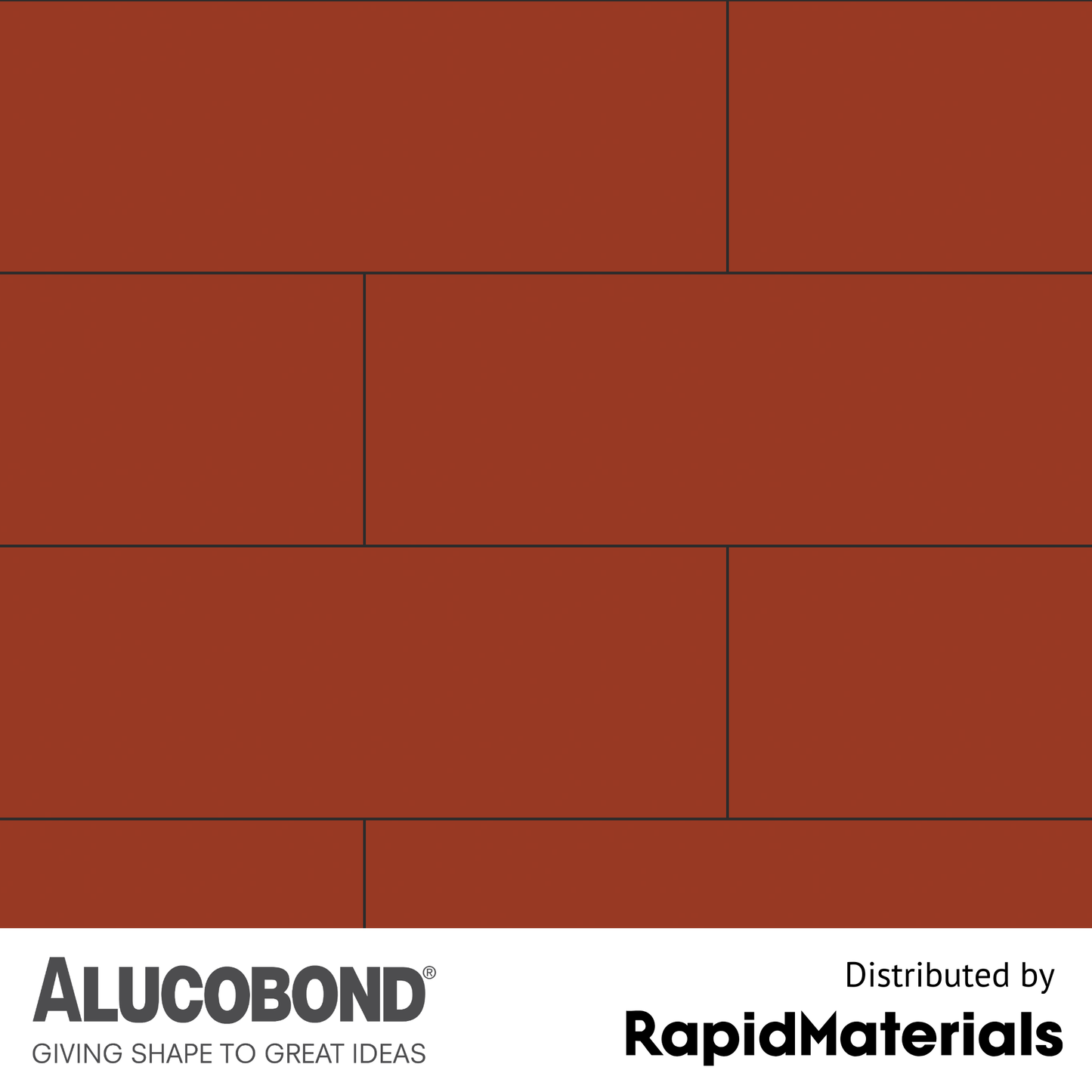

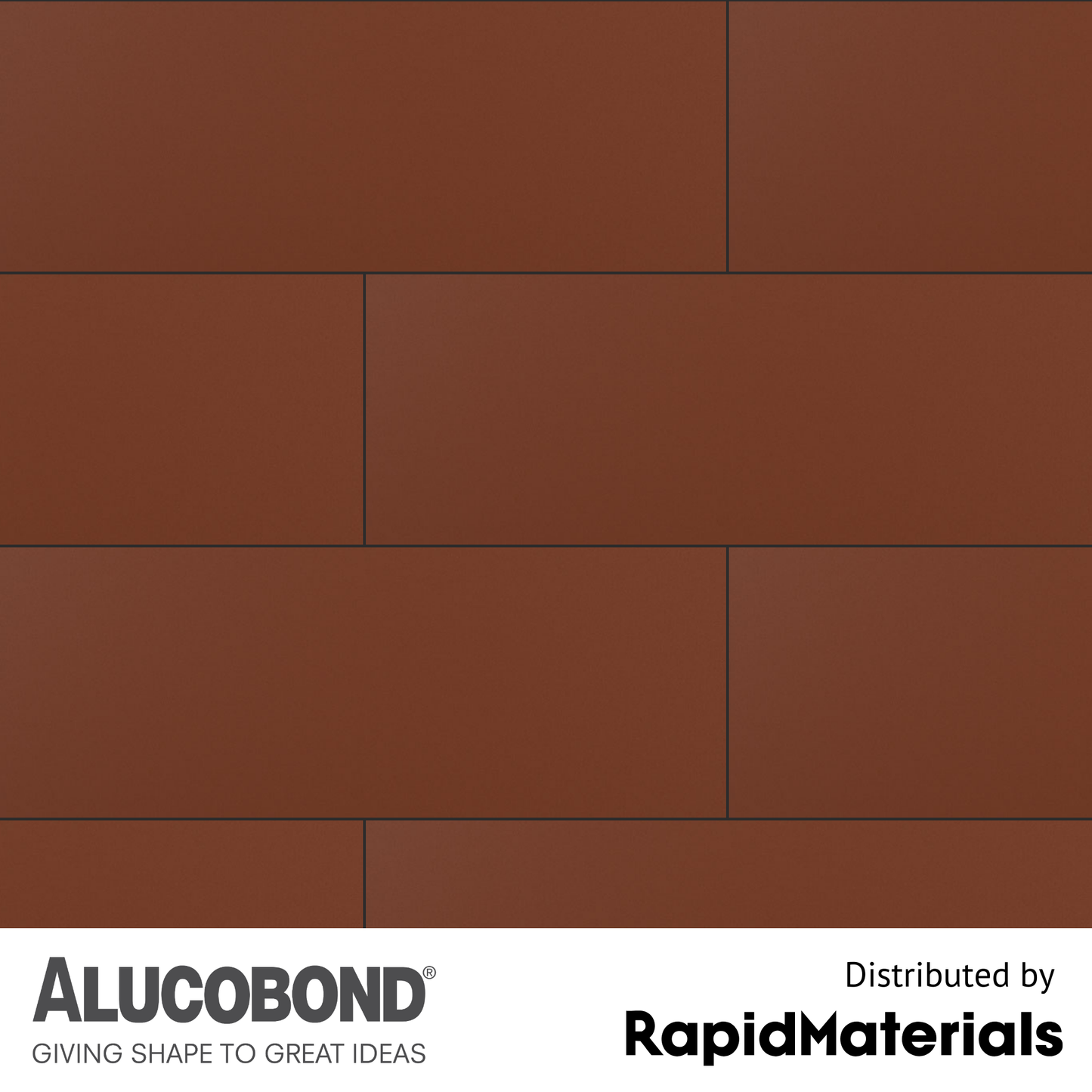

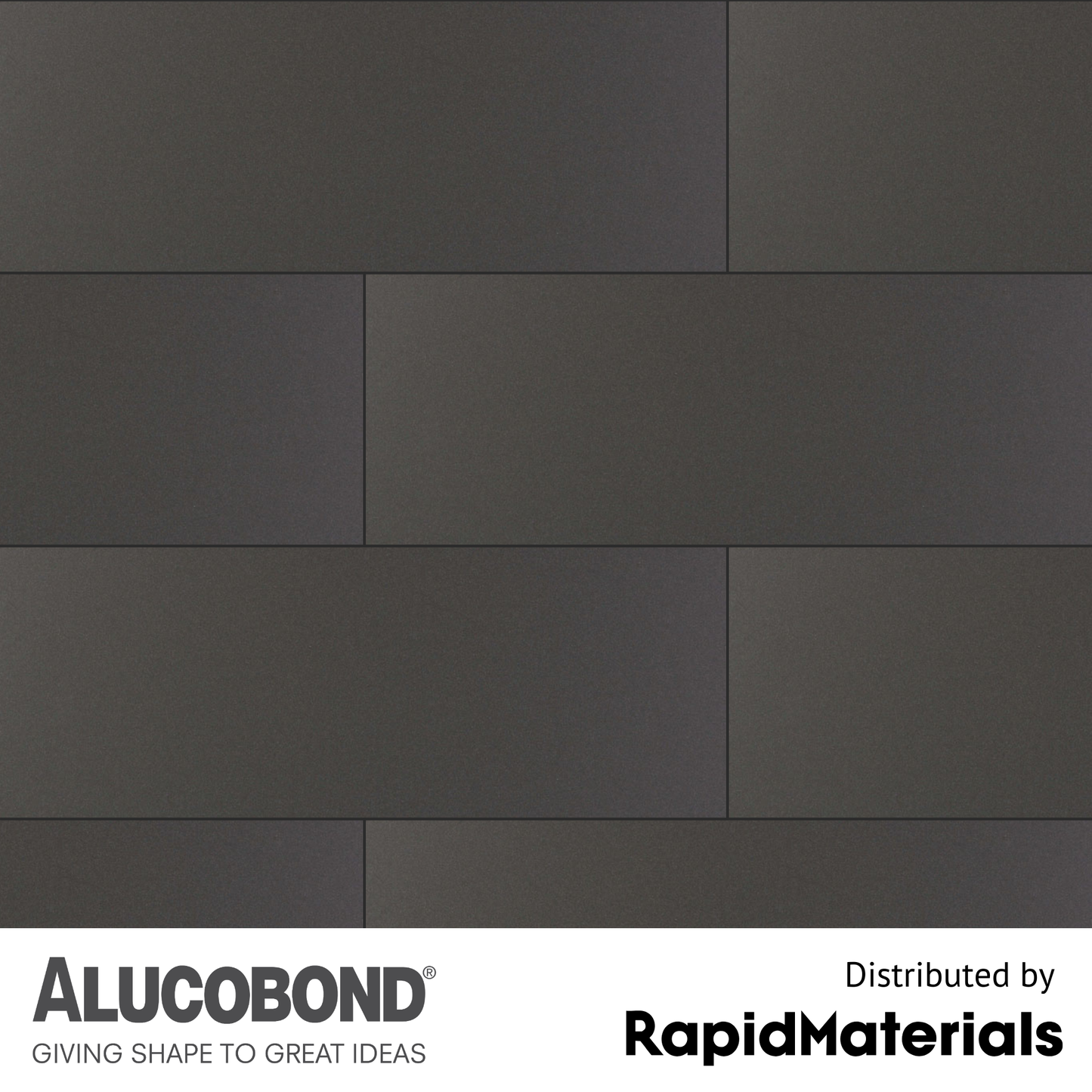

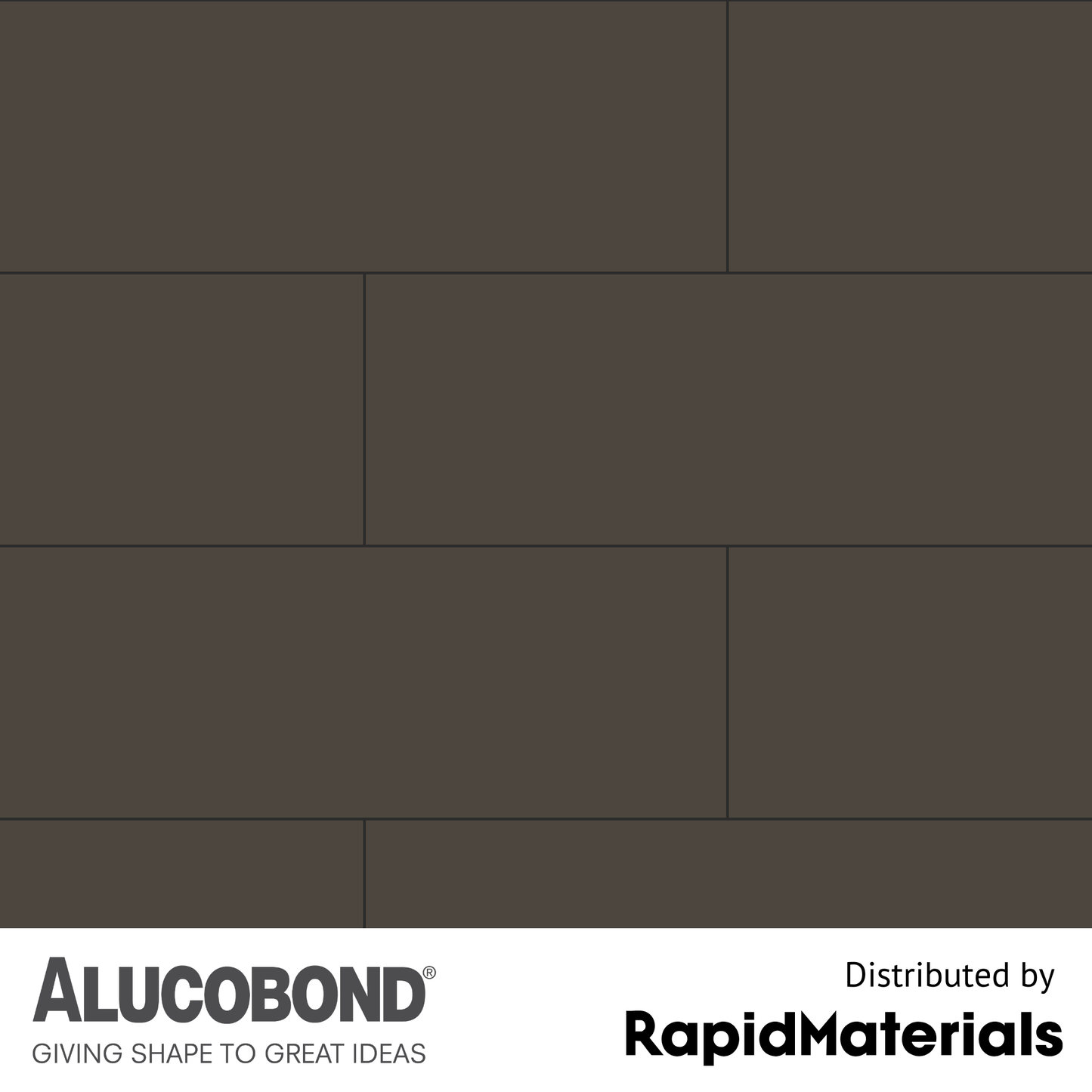

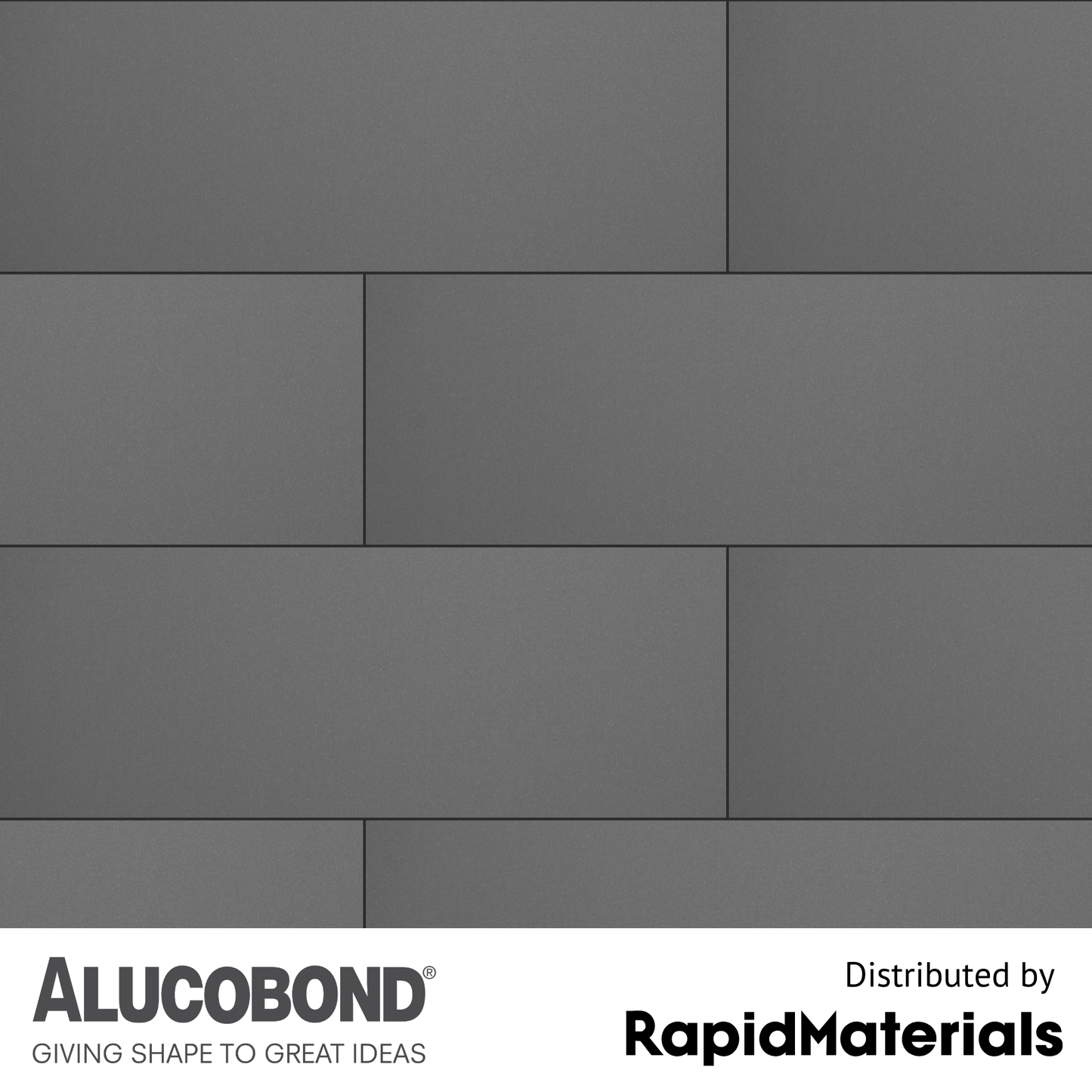

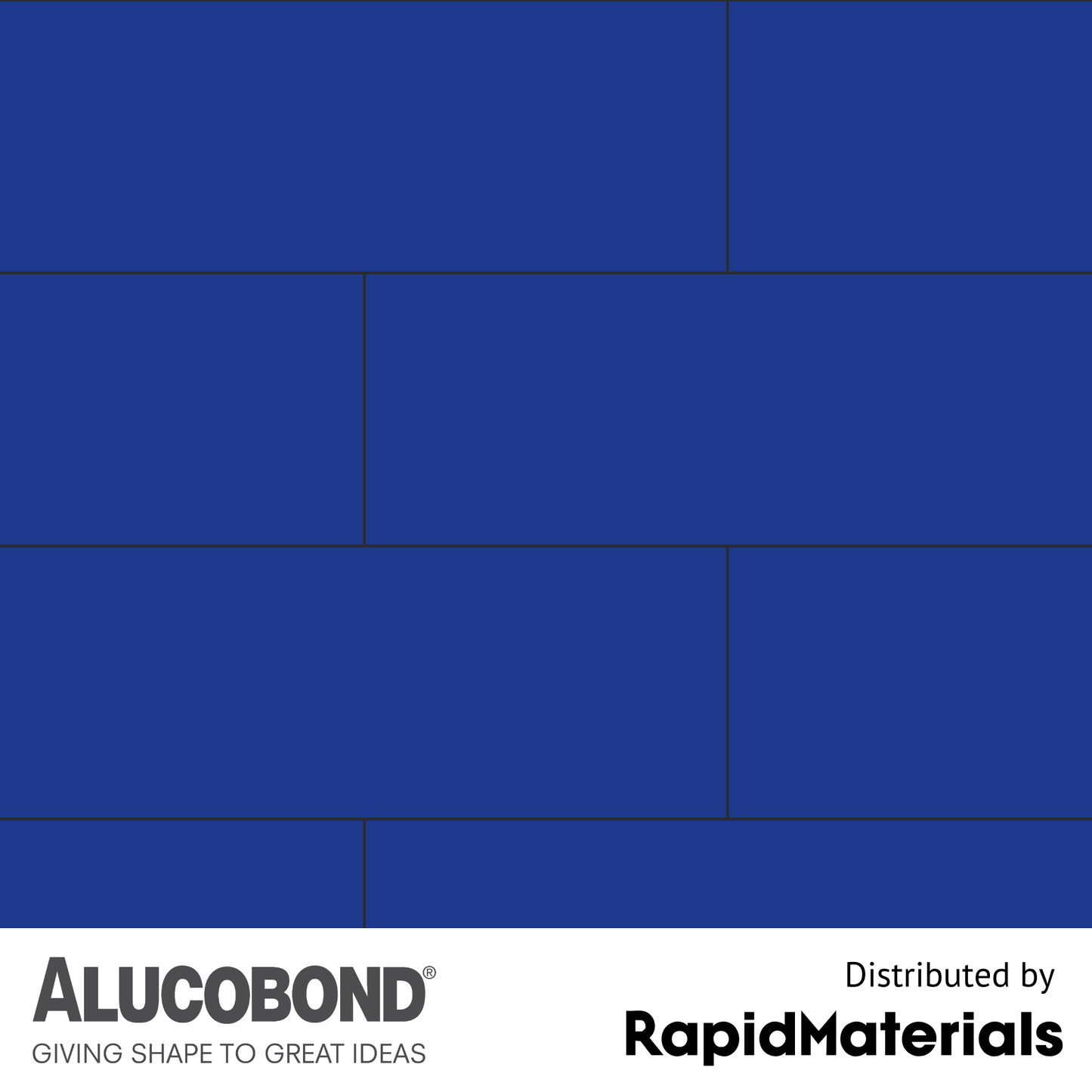

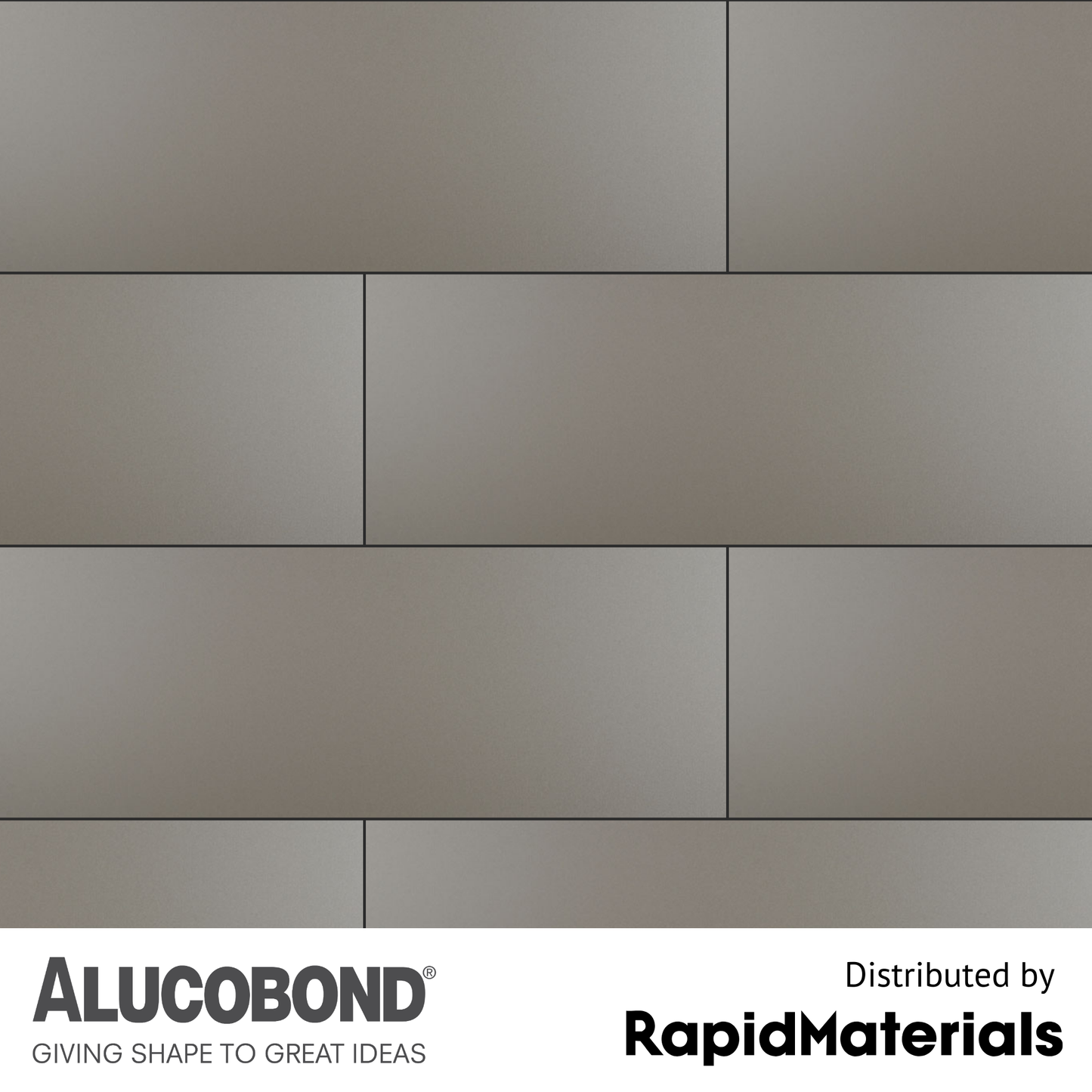

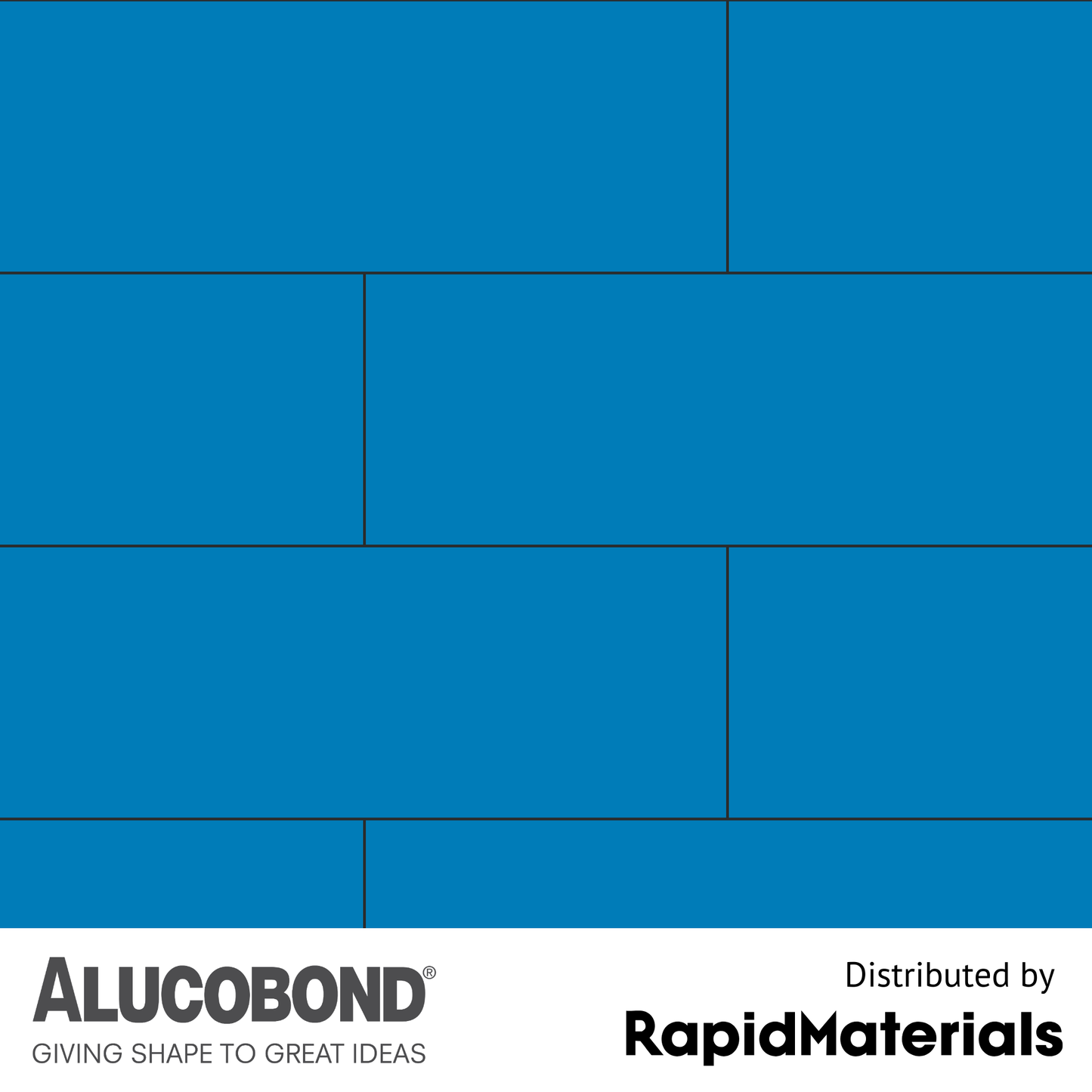

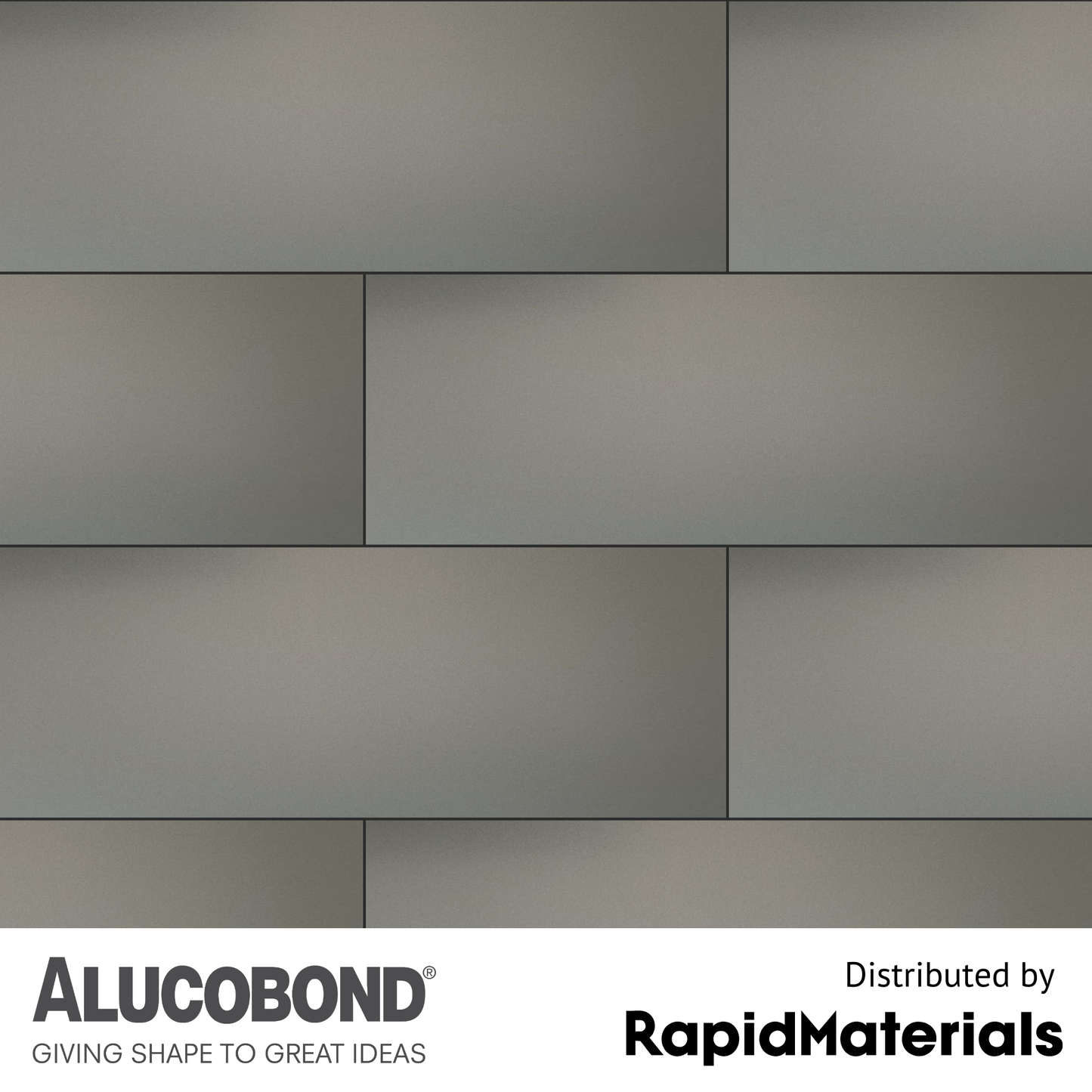

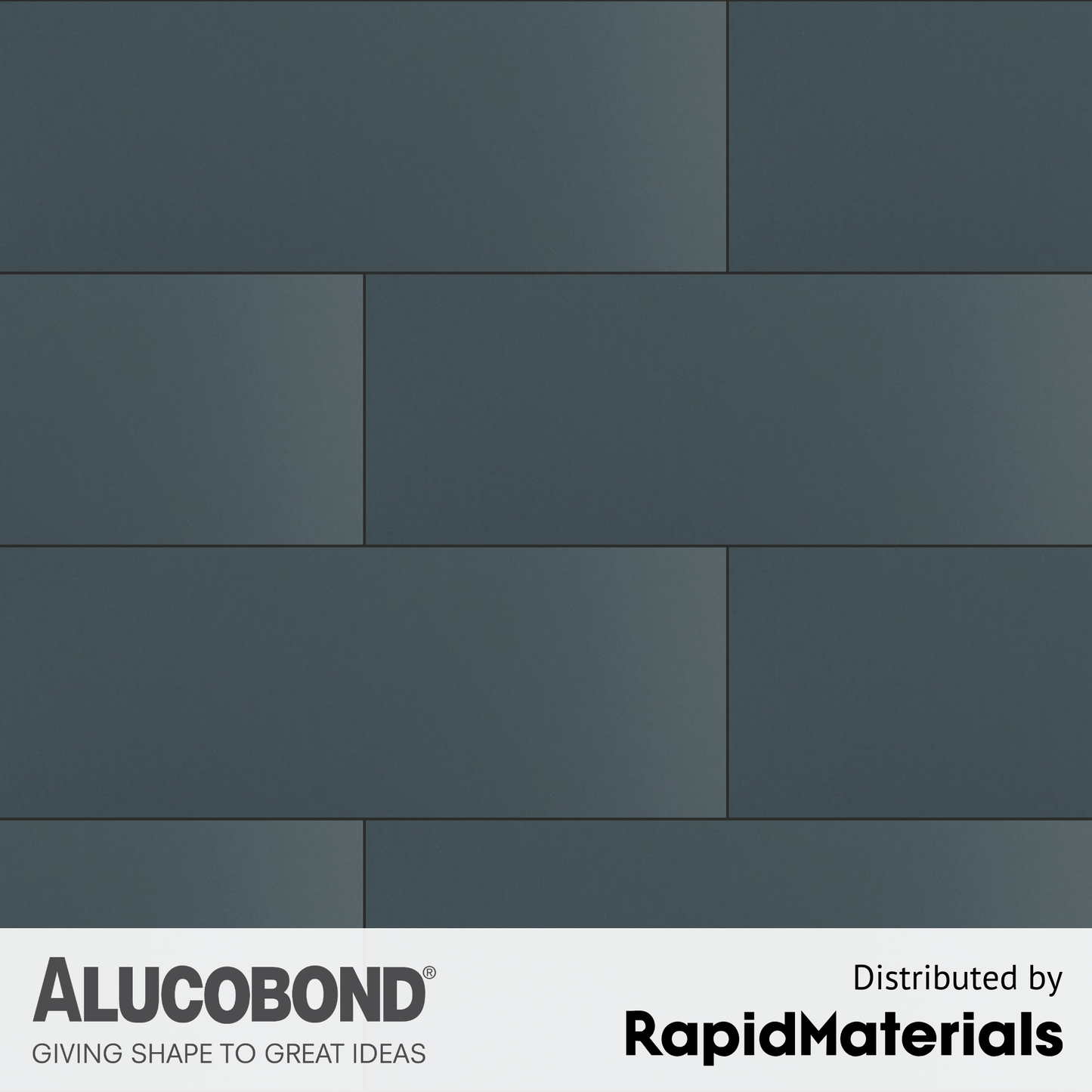

ALUCOBOND® AXCENT™ offers high-quality flat aluminum sheets designed for precision and performance. Created to complement ALUCOBOND® PLUS panels, AXCENT™ provides a cohesive aesthetic for a variety of architectural applications, including facades, soffits, trim, and signage. Available in stock and ready to ship.

-

Brand

AlucobondAlucobond® is a leading aluminum composite material for architectural facades, valued for its smooth finish, durability, and design versatility.Shop more from Alucobond →Specifications for Alabaster

- SKU: 32001000

- Direction: No

- Finish: PVDF-2

- Reflectivity:

- Coverage: Single Sided

- Thickness: .040

- Size: 48" x 120"

- Square Footage: 40.0 sq ft

- Warranty: 20 Year Warranty