SKU: 70000934 | Malco

Malco FS2F350 2-Station Metal Panel Bender – 350mm (13-3/4″ Max Depth)

Malco FS2F350 2-Station Metal Panel Bender – 350mm (13-3/4″ Max Depth)

Couldn't load pickup availability

Shipping Details

At Rapid Materials, we prioritize quick and efficient order processing to meet your needs.

Our team is available Monday–Friday, 8 AM to 5 PM EST, ensuring your orders are handled promptly. We’re dedicated to delivering your materials as quickly as possible. Have questions? Don’t hesitate to reach out—we’re always happy to assist!

Standard Shipping

- Orders placed by 1 PM EST are processed within 24 business hours and typically ship the same day.

- Orders received after 1 PM will ship the next business day.

Expedited Shipping

- For expedited orders, we’ll do our best to ship them the same day—even if placed after 1 PM EST.

Holiday Shipping

- We do not process or ship orders on major holidays.

- Some locations close during the last two weeks of the year for inventory processing. Specific details will be noted on product pages.

Please note: Some products may require additional handling time and will take longer than 24 hours to ship. For specific shipping details or lead times, refer to the individual product page or contact us directly—we’re here to help.

-

Description

The Malco FS2F350 2-Station Metal Panel Bender is designed for contractors who regularly fabricate deep chimney flashings, wall transitions, and complex architectural details. With a maximum bend depth of 13-3/4″ (350mm), this is the largest capacity model in the 2-station lineup.

Form straight 0°–100° bends on panels of virtually any length without returning material to the shop. The 2-station configuration provides controlled tracking and smooth forming across long panel runs.

Adjustable roller spacing allows precise setup for different materials, while the angled roller design helps prevent scratching at tight 90° bends. The low-profile tapered roller enables work on mechanical lock standing seam profiles.

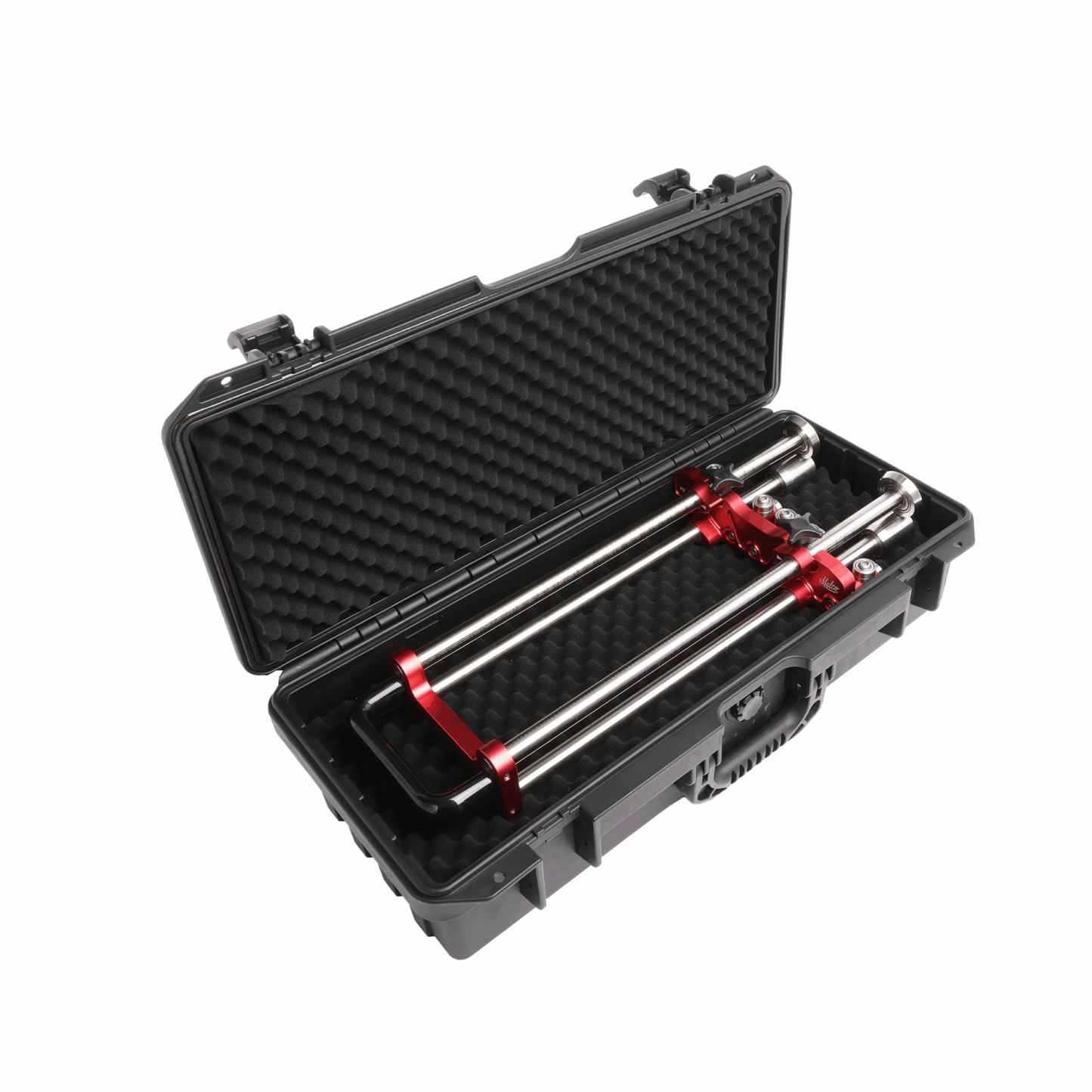

Built with premium CNC aluminum and stainless steel components for long-term durability and corrosion resistance, the FS2F350 is made for professional field use. Each unit comes packaged in a rugged IP67-rated waterproof hard case for reliable jobsite protection.

Available Models

- FS2F150 (150mm max depth) – Ideal for shallower bends, snap-lock eave work, and repetitive profiling.

- FS2F200 (200mm max depth) – The most versatile option for a wide range of field bends.

- FS2F350 (350mm max depth) – Designed for deep bends such as chimney flashings and complex trim details.

Key Features

- Forms 0°–100° bends on straight panels of virtually any length

- Bend depth range: 3/16" to 13-3/4" (5mm–350mm)

- Adjustable roller spacing: 0.5mm–1mm to accommodate a wide range of materials

- Material capacity: 24 ga steel, 26 ga stainless steel, .040" aluminum, 20 oz copper, 1mm zinc

- Exclusive angled roller helps prevent scratching on 90° bends

- Low-profile tapered roller supports mechanical lock standing seam profiles

- Premium CNC aluminum and stainless-steel construction for durability and precision

- Includes rugged IP67-rated waterproof hard case for protection and transport

- Optional 2mm Large Radius Accessory (FSLR2) allows for “softer” bends in materials like zinc and aluminum

-

Brand

MalcoMalco Tools manufactures high-quality tools for roofing and sheet metal work, trusted since 1950 for precision, durability, and job-site performance.Shop more from Malco →Specs

- SKU: 70000934

- UPC: 686046556628

Malco FS2F350 2-Station Metal Panel Bender – 350mm (13-3/4″ Max Depth)